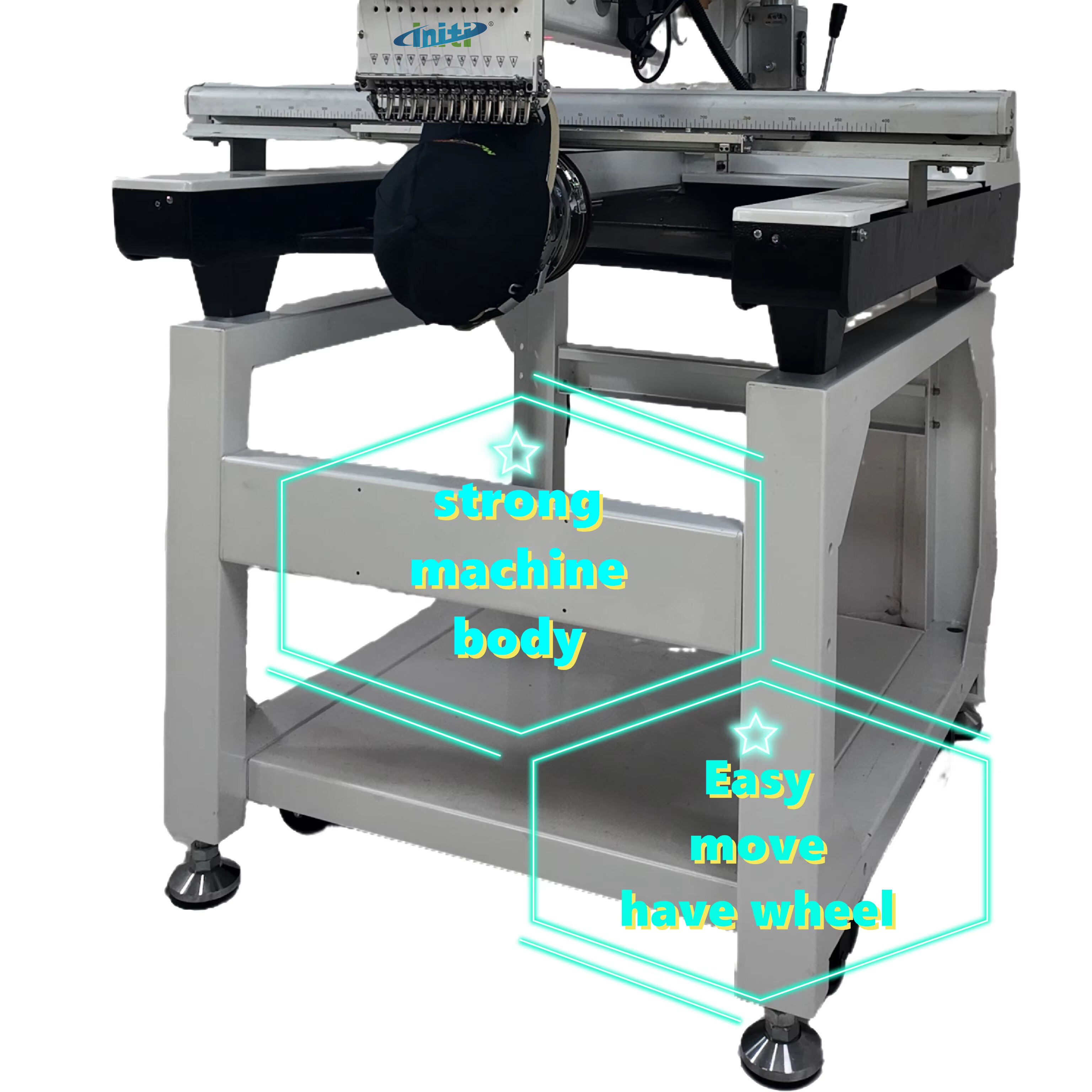

high quality commercial embroidery machine

A high quality commercial embroidery machine represents the pinnacle of precision textile customization technology. These sophisticated machines combine advanced computerized controls with robust mechanical engineering to deliver professional-grade embroidery results. Featuring multiple needle heads, automatic thread cutting systems, and high-speed operation capabilities, these machines can handle complex designs with remarkable accuracy. The built-in memory systems can store thousands of designs, while USB connectivity allows for easy pattern uploads and updates. Modern commercial embroidery machines come equipped with large color touchscreen interfaces, offering intuitive design manipulation and real-time monitoring of embroidery progress. They support various fabric types, from delicate silks to heavy denims, with automatic tension adjustment systems ensuring consistent stitch quality. The machines typically offer multiple hoop sizes, enabling projects ranging from small logos to large jacket backs. Advanced features include thread break detection, automatic color changing, and built-in design editing capabilities. These machines maintain precise registration even at high speeds, typically achieving 1,000 to 1,200 stitches per minute, making them ideal for both small custom orders and large production runs.