latest design hat embroidery machine

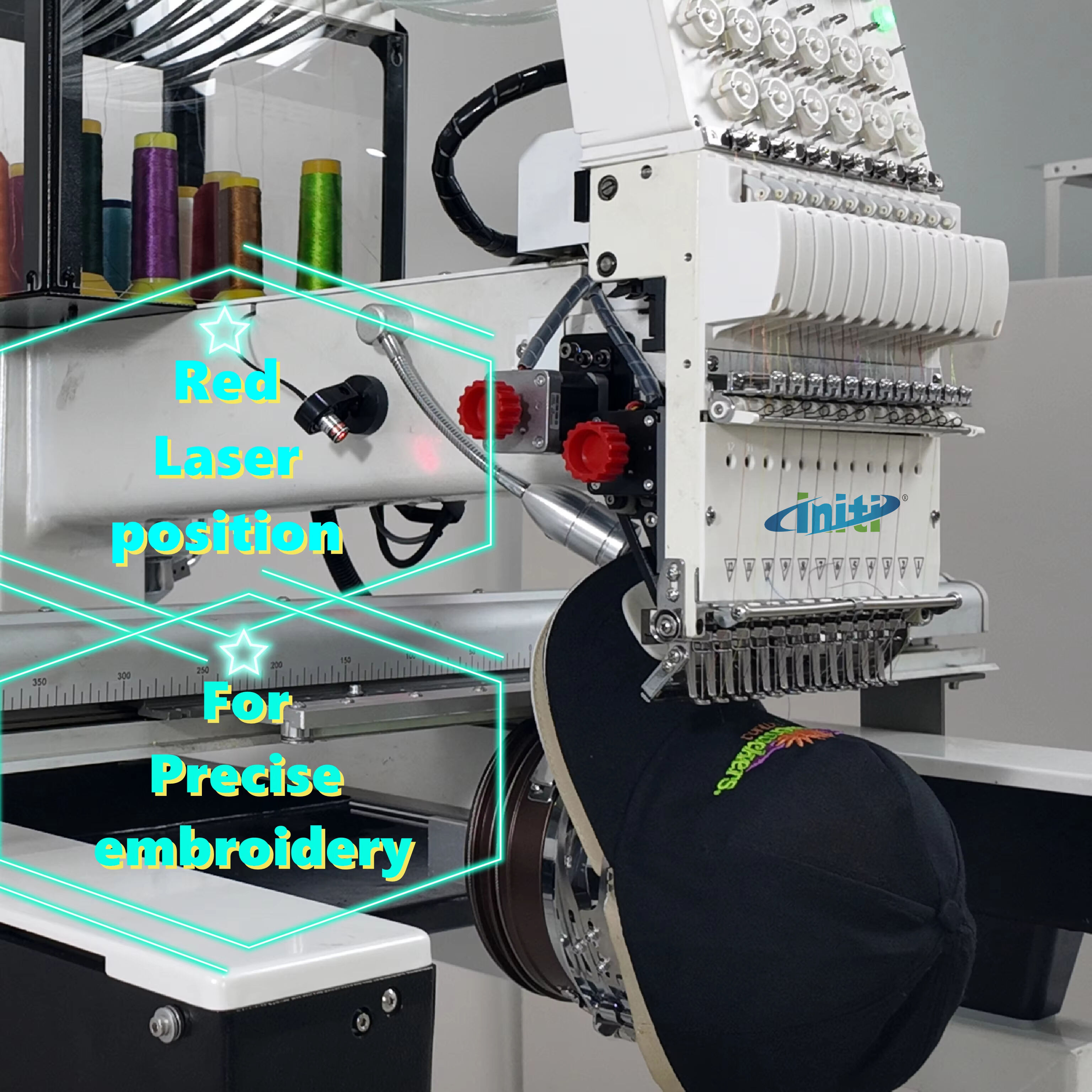

The latest design hat embroidery machine represents a significant leap forward in embroidery technology, combining precision engineering with user-friendly features. This advanced machine offers a generous 270-degree cap frame rotation, enabling seamless stitching across the entire hat surface. It features a high-definition 10-inch touch screen interface that provides intuitive control over all embroidery functions, from pattern selection to real-time monitoring. The machine operates at speeds up to 1,200 stitches per minute while maintaining exceptional stitch quality through its advanced tension control system. Its automatic thread trimming and color-changing capabilities significantly reduce manual intervention, while the built-in memory can store up to 20 million stitches worth of designs. The machine includes specialized needles designed specifically for hat embroidery, ensuring smooth penetration through various cap materials. With its compact footprint and robust construction, this machine is ideal for both small businesses and industrial operations. The innovative quick-change cap frame system allows for rapid product turnover, while the automatic thread break detection system prevents waste and ensures quality control. This machine supports multiple file formats and includes USB connectivity for easy design transfer, making it a versatile solution for modern embroidery needs.