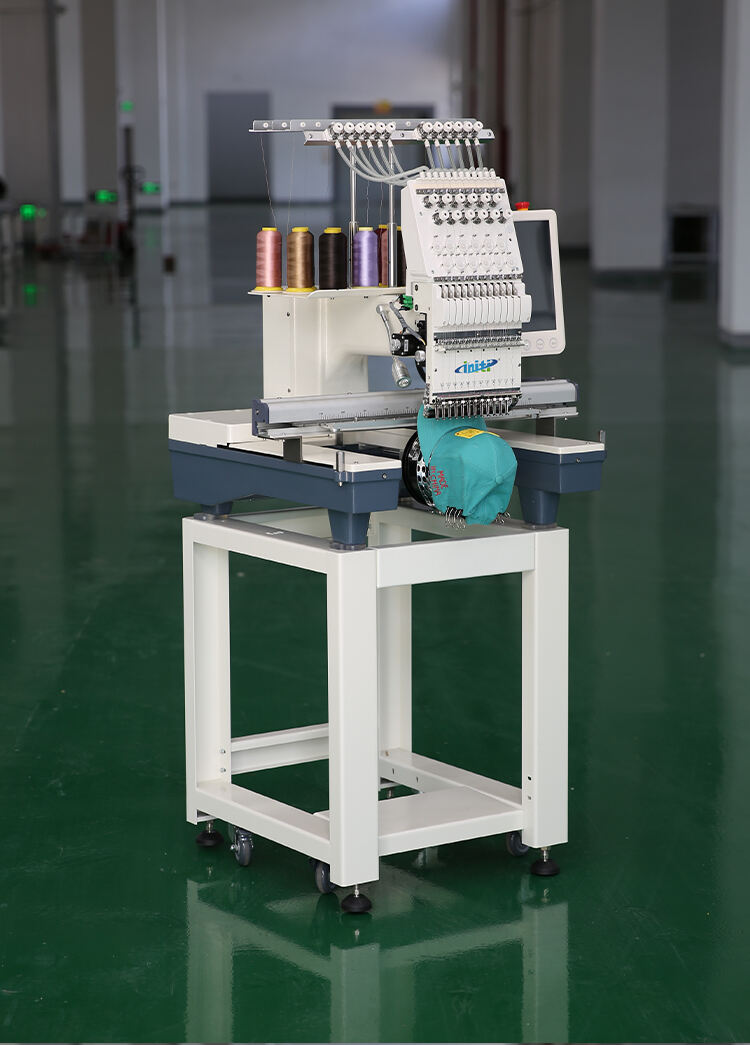

quality cap embroidery machine

The quality cap embroidery machine represents a pinnacle of modern embroidery technology, designed specifically for precision headwear decoration. This sophisticated equipment combines robust mechanical engineering with advanced digital controls to deliver exceptional embroidery results on caps, hats, and other headwear. The machine features a specialized cap frame system that securely holds headwear in place during the embroidery process, ensuring consistent and accurate designs. With multiple needle positions and automatic color changing capabilities, it can efficiently produce complex, multi-colored designs without manual intervention. The machine's high-speed operation, typically reaching up to 1,000 stitches per minute, significantly enhances production efficiency while maintaining superior stitch quality. Its user-friendly interface allows operators to easily import designs, adjust parameters, and monitor the embroidery process in real-time. Advanced features include automatic thread trimming, thread break detection, and design scaling capabilities, making it suitable for both small custom orders and larger production runs. The machine's durable construction and precision components ensure long-term reliability and consistent performance across various fabric types and design complexities.