quality custom embroidery machine

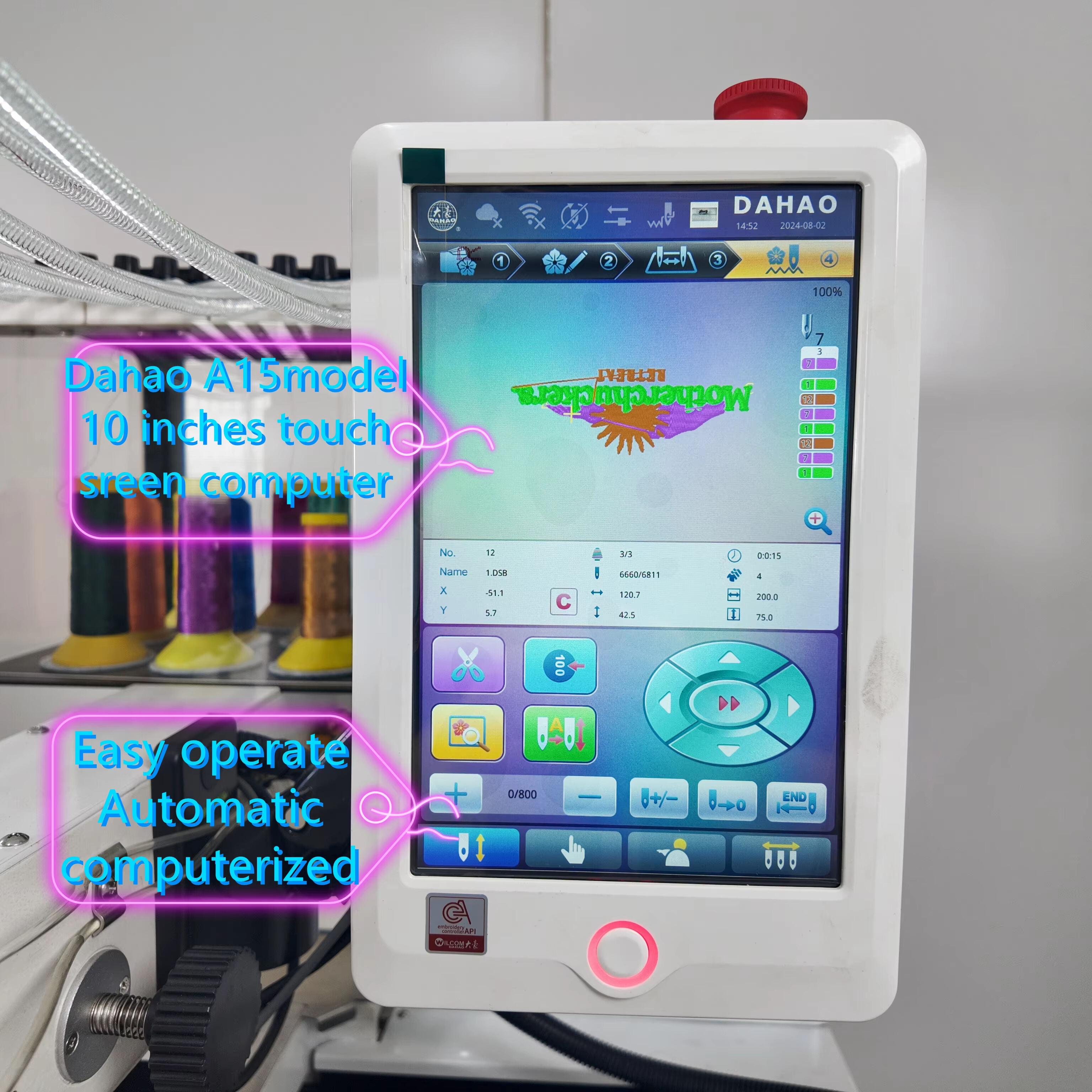

The quality custom embroidery machine represents a breakthrough in textile customization technology, offering unparalleled precision and versatility for both commercial and industrial applications. This advanced system features a robust multi-needle configuration, capable of handling complex designs with up to 12 different thread colors simultaneously. The machine boasts a generous embroidery field of 14 x 8 inches, accommodating various project sizes from small logos to large decorative pieces. Its high-speed operation can achieve up to 1,200 stitches per minute while maintaining exceptional stitch quality and consistency. The built-in LCD touchscreen interface provides intuitive control over design selection, editing, and machine operations, while the automatic thread trimming and color-changing capabilities streamline the production process. Advanced sensor technology monitors thread tension and breakage, automatically halting operation to prevent errors and material waste. The machine includes USB connectivity for easy design transfer and comes equipped with built-in memory capable of storing thousands of designs. Its durability is ensured through industrial-grade components and a rigid frame construction, making it suitable for continuous operation in demanding production environments.