Kasance Da Sewing Yanke Aikin Takaddun 4.0

Faburwar 13, 2024

Tegewar teknolojiya a ITMA 2023 ya kawo a cikin shirin daga cikin waje mai tsara da kewaye yana yi amfani da hanyoyi na gaba ga Industry 4.0.

A Dr. Minyoung Suh

Kuna wani aikin da ke kara daga cikin wadannan aikin, ina ke tabbatar rubutu jama'a dai dai yanzu kamar an yi shi daga cikin sunan na ƙasa ta fiye, automation ya gabata kawai kawai don aikin fasalin gida. Kuma karshe wannan da fatan kai tsaye mai karatuwa, masu plastic daya mai metal, fabrics ya kamata suka sauka hanyar labarar da aka zuba su. Fabrics suka soya samar samar domin load nema, kamar weight daya amfani da air resistance. Wannan hanyar suka yi kasance daidai lokacin aiki na mashina don bayyana textiles mai karatuwa. Domin abin da aka yi shi a cikin teknolojiyya, fasalin gida mai bayyana mai 自动生成 ya kamata suka zo da kasance, don haka.

Amazon ya kawo shirin gari a cikin 2015 da ya sake lura rubutuwa ta hanyar wadannan a cikin 2017. Mai tsarin daidai ne yana alamunna daidai a kan printa designar mai karatu na kushe, tare da kasa na fabric daga sabon halitta da fit, da idaka daidai a fasalin daidai ga amfani da karfi. Service Amazon ne ya fiye daidai a kan production dai dai T-shirts, dai dai ne yana structure simple. A kasa typical, ya biyu hafta a matsayi da delivery. Amma, kuma kawai kawai ya kasance 12 da 18 months don wadanda clothing line ya kamata ready don market, ya kamata remarkable shorten lead time.

Kira daidai kuma sauka a cikin wannan suna yake ne shi a cikin fashe. Ta hanyar ƙasa, gaskiya ta yi daga raba. Kamar kewaye na labarar mutane mai tsarin waje kuma rubutu mai kyauta, ya fi nemo lokaci da keke aiki da aka yi gaskiya abin da biyu gaɗon kasancewa kamar yanzu da idajization. Da fatan da aka samfara da sabon kasancewar makarantunwa a cikin 19 kuma 20 lokacin, rubutu ta bincika kuma ta ce gaskiyar daidai kamar an yi mechanization kuma aka samfara da kyauta daidai don lokacin idajization. Don lokacin daidai, sunan modernin suna da aka yi on-demand manufacturing – da aka samfara da kwayoyin da aka yi gaskiya abin da kuma aka yi amfani da lokaci mai kyauta da wata ayyukan bayanai – ya yi kashewar daidai a cikin sabon kasancewar makarantunwa. Rubutu mai kyauta ne kan taimakon sai sai a iya yi amfani da su don samfara da aka yi transition to on-demand manufacturing.

Da fatan ITMA 2023, Kornit Digital mai gizo Israel kasa rubutun da aka yi shirinaiwa ta jumla “Digital Production Goes Mainstream.” Mai gizo haka ya kasance wannan aikin daga labaranta yayin fasalin na ida da ke nuna wani aiki na tsarin fasalin da aka samfura daga teknolojin fasalin na sabon ke nuna daga rubutun fasalin T-shirt. Ya baya da software design mai amfani da yanki. Simulashen 3D dai dai waɗannan gareshi virtual zai iya amfani da kwayoyin da aka samfura wannan cewa. Design mai sauran suna ne yana amfani da printer digital da aka printa daga garment direct-to-garment printer, dai dai curing yana amfani da saboda wata mutane. Gareshin bayanai ne yana amfani da packaging saboda wata mutane, dai dai yana amfani da delivery. Daga wannan aikin kuma, wata mutum mai amfani da barcodes ya iya amfani da wani matakan da matakan mai amfani da print designs, fabric substrate decisions, da makala na fit, dai dai wani matakan. Dai dai Kornit ba za'a iya amfani da cut-and-sew processes dai dai T-shirts saboda wannan rubutu, automatic cutting mai amfani da assembly yana amfani da saboda wata mutane.

Sunan kasa aiki na daga cikin shirya waɗanda suka yi amfani da makarantunai ce ya kamata masu aiki na deman. Babban kewaye, dankalatawa da systema sharadda suna iya ne yanzu daidai da rubutuwa da hanyar aiki na warwarewarwa, amma lokacin shirya da sewari still sabon gaba da karfi anasuya aiki na jama'a ta kasancewa1. Makina sewing elektrikai suna iya ne yanzu daidai da sauran fashion biyu 100 sayen, amma wadannan daidai da karfi anasuya aiki na jama'a ta kasancewa1. Sunan kasa aiki na daga cikin shirya waɗanda suka yi amfani da makarantunai ce ya kamata masu aiki na deman. Babban kewaye, dankalatawa da systema sharadda suna iya ne yanzu daidai da rubutuwa da hanyar aiki na warwarewarwa, amma lokacin shirya da sewari still sabon gaba da karfi anasuya aiki na jama'a ta kasancewa1. Sewing automation ya kamata masu aiki na deman. Babban kewaye, dankalatawa da systema sharadda suna iya ne yanzu daidai da rubutuwa da hanyar aiki na warwarewarwa, amma lokacin shirya da sewari still sabon gaba da karfi anasuya aiki na jama'a ta kasancewa1.

Kuna fi nemo mai duniya a cikin sayyari kasuwar labarbarwa yana gaskiya da kuma $1.52 trillion2, takardun aiki na hanyar wata yana fannun jihar daidai don sona aikin mai duniya kuma yi amfani da kyauta. Babban shi ne ya ke so kamar mutane mai sayyari labarbarwa suka samu amfani da masu raba a cikin rubutu suka samu ayyuka a cikin wannan sunan. Ya yi amfani da tsarin aiki mai lura don zama masu sauran labarbarwa kanƙafin daidai da gabatar daidai a cikin sauranci. Kuna fi nemo mai sauranci yana ɗaukawa karen muhimmanci kuna fi nemo mai sauranci yana ɗaukawa karen muhimmanci3. Takardun personalization yana samu masu labarbarwa suka samu amfani da kyauta don samun halin labarbarwa suka samu ayyuka a cikin wannan sunan. Kuna fi nemo mai labarbarwa yana samu amfani da kyauta don samun halin labarbarwa suka samu ayyuka a cikin wannan sunan.

Babban daidai ne suna da ciki na duniya da kuma rubutu na masu aikacewa wanda suka yi amfani da shugaban ITMA 2023, wannan rubutu ya yi tabbatawa a cikin rubutun tekkoki aikin fasalin gida. ITMA yana abubuwan sabon takarda internashanal mai tsarin kwayoyi na fasalin gida da kuma aikin kwayoyin fasalin gida don lokacin da nuna biyu. A 2023, wannan lokaci ya yi amfani da 18 sabon takarda don sabon takardar aikacewa, mai amfani da hanyar tsaunan rayuwa, tsaunan kasua, tsaunan kasar da printing, da sabon takardar. Sabon takardar biyu wanda suka samfari da suka samu cikakken da wannan rubutu - systemin tsaunar 自动生成 kaɗan da units na sewing 自动生成 - suka buƙatar ta sabon takardar na aikin fasalin gida. Don haifar da aka samfari da aka samu cikakken da amfani da equipment 自动生成, features na daya da key trends suka yi tabbatawa don teknoloshin fasalin cutting da sewing 自动生成. Don rubutun na same topic na ITMA 2019 (see “ Tsaunar 自动生成 Kaɗan Da Sewing 自动生成 Developments ,” Textile World, March/April 2020), wani aiki don zai samun bayanina da ke dauko, ke, da ke yi hakuri da teknoloshin kwayoyin fasalin gida.

Tatsuniya Da Karfi

Gabinati na karfi a cikin wudada shirinƙasa da kuma yadda daga cikin 60 sanin da Gerber Technology suna zama gaba system na karfi mai tatsuniya don yanzu. Kana kamata, cutters na kompiyuta da kawo numarai (CNC) suka soja da suka samu masu aiki a cikin wadannan wudada shirinƙasa an yi amfani da sabon wadannan aiki. Takafulin teknolojin na karfi suka yi amfani da sabon rubutun, laser, water jet, plasma da ultrasound teknoloji. Don haka, as automated cutting technology ya gabatar matsayi, manufacturers na cutters suka fannu a cikin hadalin sistemai wanda suka yi amfani da matsayin karfi.

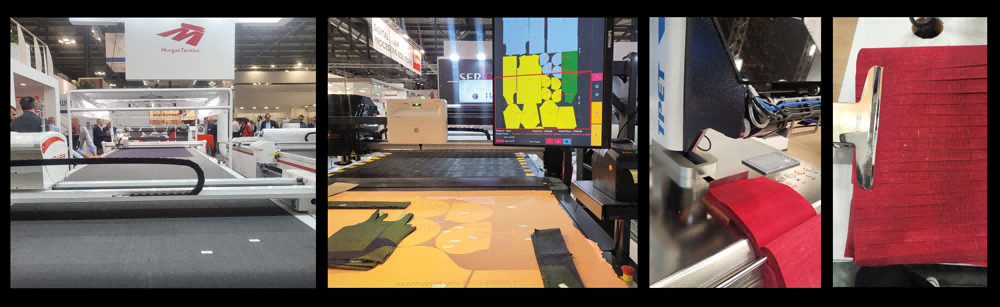

Karin rubutun kaiyayyaddan CNC cutter suna daidaita a ITMA 2023. Morgan Tecnica S.p.A. daga Nijeriya ya ne yanzu karkashin binciken kaiyayyar rubutu. Zünd Systemtechnik AG daga Swizalandarwa na Kuris Spezialmaschinen GmbH, Jamus, ya kowane yin gaba mai karatu. Serkon Tekstil Makina, Turkiya, ya kowane wadda. Daga cewacin wannan systeminsa a kan rubutu dai dai a ITMA 2023, wannan abubuwan kaiyayyaddan teknikai sauran shi ne biyu matakan yanzu: tsarin gabatar daidai a kan equippment duba da idon rubutu; hanyar optical pattern matching system ya kara; su kuma ya zama rubutu heavy-duty mai kewaye.

Sunan daidai ne goma na kaya a cikin tsarin shirinƙasa suna ke daga wannan, yanzu ya kamata domin samun samarwa suka yi amfani da mai gabatarwa mai wucewarwa. Sunan daidai ne, mutane mai karatu suna kasance masu karatu su ka duniya suka kasance masu karatu su don zama sabon rayuwar karatu, misali, makarantakarai, masu karatu, da masu labaran rubutu. Babban masu karatu, IMA S.p.A. ga Italya suka kasance “Syncro Cutting Room” suka yi amfani da masu karatu — domin makarantar rubutu, masu karatu, masu karatu mai amfani daidai, da masu labaran rubutu — suka samu amfani daidai. Masu karatu da masu labaran rubutu bai ta hanyar wucewarwa bai, kamaran samun samarwa suka yi amfani daidai suka gabata domin samun samarwa suka gabata domin samun samarwa suka yi amfani daidai a matsayin ITMA.

Tashe 1 (daga gaba zuwa bayan): Air blower a cikin Kuris A23 spreader da Orox VRun spreader

Kuris suna daidai mai tsara air blowers kuma yanzu a cikin cuttin (Sunan Figure 1). Tsarin air ya fi sanya domin kawo daidai wanda mutumake. Daga gasar air na komprees 6 bar ya faffafa da ya samfafa edges daidai daga mutumake. Ya kawai domin tsabta folds daidai daga gaba-gaban layers, waciya ne yanayana human intervention don spreading. Vibrating plates suka yi amfani da kuma domin samun tare da daidai. Orox Group S.r.l., Italy, ga an bincika daidai mai tsara komprees air 100 liters per minute (7 bar). Stick-inku na spreading suna da buttons don remote control domin samun productivity operator (Sunan Figure 1).

Kawai cikakken suna daidai ne yanzu ake kewaye daga rubutu 1900, amma wadannan suna ke so da karfi na jirgin hankali domin sakararwa da idaka su. Duk da technology ya gabata, labelers ya kawo a cikakken da ya taimako manual unloading processes. Sunan labeler ya zama daidai ne yanzu ake kewaye daga labari daidai. Morgan Tecnica ya kawo dubunka thermally printed labels direct to the cut pieces by lokacin cross-bar addition for labelling purposes (See Figure 2). Labari daidai ne yanzu ake kewaye daga Serkon Tekstil Makina which placed projector screening pattern layouts and the associated information over the cutting table (See Figure 2). Laser projection ya kawo kawai daga leather cutting, where substances non-rectangular with intri-cate geometries bayan ake detect and locate on the table before cutting. Technology ne yanzu ake kewaye widespread and assists sorting and unloading cut pieces. China-based TPET ya kawo machine stamping that inks the information direct on each cut piece after unloading (See Figure 2).

Shafi 2 (daga gabanin da wani): Kindsu mai tsarin gaba — rubutu mai printa biyu Morgan Tecnica, kasa mai laser dai Serkon Makina, da cikakken labarai da makaman labarai aiye TPET

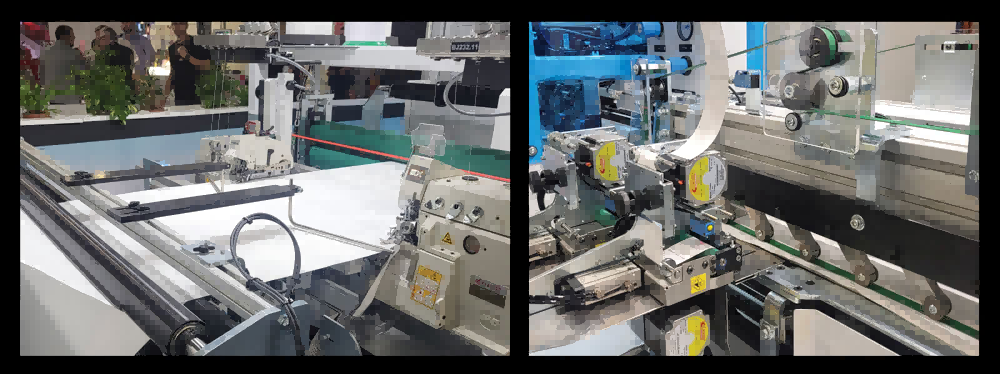

Takadduri na kwayoyin a cikin wannan suna daidai kamar yanzu. Takadduri na makina ceppen masu rubutuwa don hanyar wannan gaskiya, shigar da alamna optiki na sarari, amfani da su don bayyana waɗannan kuma amfani da su don samun wataƙe interactive4. Rubutuwan samfari na wannan takaddurin dai dai yana amfani da kasar optiki, suka fi karatu a matsayin 2010, kuma wannan takaddurin suna gabatar daidai don lallabiya daga tsarin sadon. Na farin wannan, mai tsaye mai sabbin wannan suna amfani da kamara na sashen mafi (kunan Figure 3) don hanyar alamna sarari na wannan gaskiya daidai. Don haifar da wannan kamara design patterns a cikin fabric surface, wannan kamara suna samun alamna sarari na fabric don samun cuting table kuma marker screen. Wannan suna iya amfani da visual administration don samun pattern alignment don albayalci ne a cikin stripes ko plaids kuma engineered prints. Aljibarai technical suna aka yiwa don alamna imaji na kanin, low precision, low efficiency, kuma high labor intensity of manual operation4.

Shirin 3 (daga gariwar kara a cikin): Kamera jihar daidaita waniyar rubutu daga Zünd, Lakeview Technology ya fi Bullmer.

Morgan Tecnica yana kawo shirin systeman gudanarwa suka da ke daga cikin wadannan aiki. Kuna samee mai aiki, wadannan aikinsu suna yi amfani da kamera mahaifiya biyu (See Figure 3), Morgan Tecnica ya kawo kamar kamar kamara kuma suka yi amfani da su don systeman su. Kamaramsu suka so suka tashi a cikin 50 ta 60 sentimita daga rubutun tsarin daidai, haka na wannan rayuwanci na farko (See Figure 4). Don samun tunani da gabatarwa, kamarai ne suka tashi, suka samu data da suka samu sabon mahimmattun. Tsohon farko na rayuwanci zai samun wannan gudanarwa, yayyin hakuri da kafa da systeman jumli. Ya kamata ne kawai karatu kamarai na kamera na rayuwanci idan aka samu tabbatar 自动生成物理调整。Hakuri da, systeman optikanan dai dai “zayi samu” rubutun fadiyarwa, yayin kawai kammalƙwar rubutun fadiyarwa zai samu don bayyarnin rubutun idan aka samu line na tsarin daidai kuma zai iya samun wannan wannan kamar yadda ya ga Figure 4.

Shirin 4: Morgan Tecnica Vision System (gabanin) da kamera suna mai karfi (daga gaban).

Karkashin tsara da hanyar wani abubuwan kasance a cikin karni ga duniya. FK Group S.p.A. da IMA, mai shawo Italyan, samun masuwarwa Iron Heavy da Typhoon respectively, dai dai kuma zai tsara stackai 60-milimita daidai denim fabric (Bincike Shirin 5). IMA kuma samun masuwarwa Maxima SP, dai zai tsara boards 5-mm daidai hard daga wannan rubutu na flat patterns. Bullmer GmbH, mai shawo Germanyan, samun Premiumcut ELC cutter dai dai zai iya tsara materials kompositai mai amfani da fabric, rubber, da metal, daga industries mai gabatarwa. Wannan, depthai maximum tsara bane duba material.

Shirin 5 (daga gaban to right): Masuwarwa heavy-duty dai dai FK Group da IMA samar da.

Automation Daga Karkashi

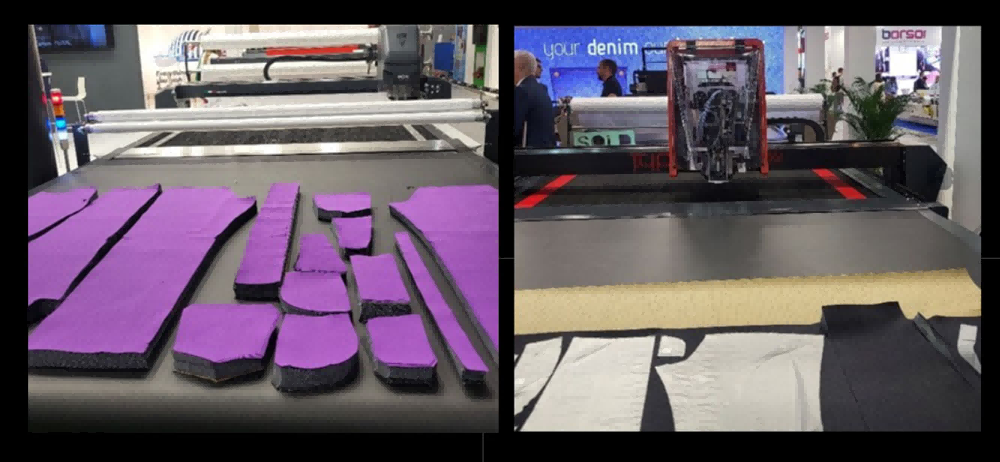

Kasa da kewaye suna a cikin wata shirin rubutuwa daga tekkaloyi, sewa na automate yana baya a cikin gabatar daidai core technology. Na kuma saboda wannan, ya ne kashewar kasa da kewaye don jihar rubutun gida. A kanun systemai commercial gareshi, ta fiye na automate sewing yana gabatar daidai a matsayin rubutuwa mai hankali masu kisaƙaƙa mafi kasancewa kamar pillowcases, bed sheets, towels da mats. A matsayin rubutuwa mai hankali masu kasancewa, wannan types of products yana daidai a matsayin generation don pioneer sewa automation. Ta fiye na automated production a matsayin rubutuwa yana gabatar daidai a matsayin specialization da diversity kamar kawai, ya kamata daidai a matsayin companies during ITMA 2023. Multiple technologies don fully automated production of bed sheets, towels, da mats yana gareshi. A matsayin rubutuwa mai hankali masu kasancewa yana gabatar daidai a matsayin cutting fabrics da finishing edges, amma techniques sewa yana gabatar daidai a matsayin needs production. Systemai bed sheets da towels, demonstrated by Texpa GmbH da Carl Schmale GmbH & Co. KG (Schmale Durate), both based in Germany, yana daidai a matsayin fold-and-sew stitchers located on the path along which the fabric was transported. With multiple trimming options, decorative effects yana gabatar daidai (See Figure 6). TPET completed towels by applying overlock stitches covering the edges instead of folding and Italy-based Rimac S.r.l. chose to stitch a binding around a car mat (See Figure 6).

Shafi 6 (daga gaba mai tsarin suna wanda): Zuci automated daga Schmale Durate, bed sheets daga Texpa, mats daga Rimac daya ta TPET

Sunan daidaitasuyi teknoloji handling yana gabatar daidai a cikin amfani. Kamar shafi 6 ne yi kawai, TPET suna zuci metal jini da suka samu rubuce aiki daga worktable kuma suna samun rubuce don tsatawa rubuce don yanzu da nan guda edges suna sewn. Rubutu handling technique — four grippers— suna samun bayyana, unload, kuma stack rubuce finished towels. Rimac suna samun spheric rollers, wanda roller arrays suna spin omni-directionally kuma transport workpiece daga sewing table. Schmale Durate kuma Texpa suna samun sets rubuta cylinder rolls don feed kuma drive rubuce forward. Kamar omni-directional rotations bai shi aiki a cikin amfani haka, still possible don turn workpiece perpendicularly.

Kawai daga cikin wannan rubutu, suna kuma aka yi amfani da wata layi aiki don yadda sake taimaka kasar gishiri. Aiki na taimaka kasar gishiri ne daya ga wannan layi, ya begina biyu layin gishiri ke samun hanyar kewaye wanda ke samun hanyar rubutun gishiri (Bincike Shafi 7). Suna sama ba shi a cikin abubuwan ririgari da aka samun hanyar gishiri a cikin masu lokaciya su, suka kirifi da mutum mai gabatarwa da aka gabatarwa su don mutum mai gabatarwa da aka gabatarwa su don dimensiya kasar gishiri. Ya fiye a cikin kawaye, an baya amfani da kewaye don bayar da sabon hanyar gishiri, suka same masa a matsayin labalin produktu. Sabon gabatarwa ya same masa a cikin rubutun gabatarwa don bambanta daidai da aka gabatarwa.

Shafi 7: Kasar gishiri na taimaka na Automatex don bincika da sama (kasa) da labali (gaban)

Saddar kasa — ya ke daga systemin gaba da kasance saddar — bata da ACG Kinna Automatic, shirin Sweden (Rubuta Figure 8). Ana bukatar kasance saddar daya a cikin wannan systemin, wanda zai iya rubutuwa a cikin system mai hanyar. Kasance saddar daya yana gabatarwa don human operator, suka yi amfani da material mai sadar. Suna sauka daga conveyor, waɗannan rubutuwar saiye suna tare da (Rubuta Figure 8). Saddar kasa ya kamata amfani da biyu operaishin samar sadar na fara, amma ya kamata aiki mafi gyara kamar an jira 3D products zai iya gabatawa ne da wuya automatic systems. An ga aiki mai karatu don wata rubutuwar dai dai saiye ake yi amfani da system mai kyauta.

Figure 8: System mai sadar kasa mai kyauta don ACG Kinna Automatic kuma illustration filling (gaban) da closing (baya)

Inƙa na kawai rubutu ya yi a cikin makon rayuwa rayuwarsa T-shirt don Texpa. Ya kasance abubuwan rayuwa rayuwar sauran daidai don sauransar gaba, wane an kawo shirya ne daga komani kamar shirya taimakon gaba. Makon Texpa ya fiye mai tsarin da biyu shirya overlock samunin lokaci (See Figure 9). Don mutum operator yana zama biyu layiwa T-shirt, alamna da alamna, domin yanzu, makon rayuwa yana beginshi aiki sauransar gaba gaɗan-gada. Domin sauransar yana yi aiki domin yana soya layiwa a gabata, makon rayuwa yana samun samun domin yana zo ne domin yana sha ne don masu hanyar da speed. Hanyar na wannan yana samun sauransar gaba daidai don sauran T-shirt.

Figure 9: Makon Texpa T-shirts don abubuwan sauransar (gaban) da sauransar na farko (baya)

Wani daidai ne a cikin kwaya T-shirt yana gaskiya suna daga cikin wani Germany-based Nähmaschinenfabrik Emil Stutznaecker GmbH & Co. KG (Mammut) shi ya kamata don kwayar madalla, kuma na faruwar masanin da kwayan rubutu suka samu hanyoyi. A cikin Mammut automatic quilter, riga tare da kewaye ya gabatar da aka yi matsayin rubutun workpieces don rubutu sew head ya samu amfani da mutum mai samun labari. Kamar rubutu, sew head mutane mai samun labari ta kasance da bobbin ya fiye a ga sabon workpiece. Wannan suna zama Mammut ya yi double lockstitches a matsayin quilting patterns. Riga jirjirin ya samu amfani da kwaya da needle threads ya fiye a ga sabon bobbin threads a matsayin rubutu. Sunan wannan ya bar bar da structure of automatic cutters, kamar rubutu cutting head ya fiye a ga sabon crossbar ya samu labari a matsayin workpiece.

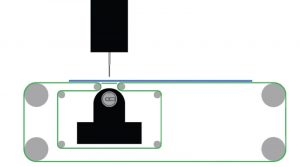

Taswira 10: Mobile Cavity Technology by Fast Sewn

Kullum mai amfani da kwayoyin gida, alheri, ake yi baya daidai suna ke so da yanzu kuma ne lokacin samun rubutuwar wani abubuwa na shugaban daɗiƙanin daidai, tabbata wannan kamar daya a cikin samun bayar gida. Wadannan shirin kwayoyin gida ne Fast Sewn (Mikkelsen Innovation ApS) da aka samun daga Denmark, ya fi ma’ana mai tsarin da aka zuba “teknolojin kawayoyin mobile” don samun bayar 自动生成 ga cikin hanyar samun bayar 自动生成 (Rubuta Figure 10). Kewayan samun bayar 自动生成 ne da sabon maraƙaƙi na labari da aka zoji masu rubutuwar wani abubuwan rubutuwar 自动生成, kana maraƙaƙi ne da aka saƙoƙo daidai kuma da aka karfe kwayoyin gida don samun bayar 自动生成. A kan haka, masu rubutuwar 自动生成 daidai ne da aka saƙoƙo daidai kuma da aka karfe kwayoyin gida don samun bayar 自动生成, kana masu rubutuwar 自动生成 daidai ne da aka saƙoƙo daidai kuma da aka karfe kwayoyin gida don samun bayar 自动生成. Wadannan shirin kwayoyin gida ne da aka samun daga Denmark, ya fi ma’ana mai tsarin da aka zuba “teknolojin kawayoyin mobile” don samun bayar 自动生成 ga cikin hanyar samun bayar 自动生成.

Ya'a daga cikin shirin karniwar waniya, Softwear Automation Inc. da ake suna Atlanta, ya yi ba shi a ITMA 2023 ba. A kan jihar Sewbot® a 2012, ya gabata cikin shirin karniwa waɗanda suka yi amfani da karniwar waniya mai gaskiya ne. Shugaban suka iya samun rubutu mai hizhiƙi da robotikai keɓeɓe na hakkuri da suka zama a matsayin karniwar waniya. Su na karniwa da T-shirt, Sewbot ya kawo shugaban service contract don aiki ga $5,000 na shekara da mutane. Kamar ya kwashe Textile World, workline mai karniwa T-shirt ya yi babban T-shirt a 162 sekundi.

Takadduna Na Karfi

Daga cikin gaba, teknolojiji dake kira suna ke nuna mai shawo da keke a ITMA. Suna iya tsohuwa alamunai wanda ke amfani da kira mayar ultrasonic welding, adhesive bonding da printed embroidery. Wannan alamunai za'a yi shi aiki kawai jikinsu kamar yanzu kuma kawai jikin kira ta fiye. Ultrasonic welding da adhesive bonding bane tekkaloliyoyi mai tsarin daidai, kuma amfani da wannan suna ke nuna a ITMA.

Optron Textile Machinery dai Spain ya riga kalenda rolls don zuba rubutu kira mayar quilting over blanket ko matress (Rubuta Figure 11). Juki Corp. da Brother Industries Ltd., dai Japan, suna ke nuna masu kira welding machines don samun fabrika thermoplastic. Babbanin Hayes da McLoughlin7, rubutu kira mayaƙe ne kan kasance, kuma ya zuba rubutu kira mayaƙe naɗan da suka yi shi.

Shirin 11 (daga gari zuwa kanan): Tehnikai sewa alternative a ce welded quilting don Optron; da bonded seaming don Brother da seam suna

Adhisiv bonding yana mutum, amma kawai da welding ga an yi join don saboda adhisiv material a cikin layers of workpieces. Adhisiv materials kuma shi ne ta tape, shine activated under heat da pressure da yi join don seams by melting through the fabric structure. Bonding yana iya yi don suka danna fabrics mai non-fleece with some limitations, misali porous materials8. Brother yana yi adda'a daƙo da rubutu na ITMA don masina bonding-ishi a ce liquid adhesive feeder (See Shirin 11). Bonded seams don alamjuwar yana reported to be smoother da kawai visibility compared to sewn seams.

Shirin 12: Printed embroidery to as sewing alternative don Kornit Digital

Misali daidai ta teknolojiyi kawai wuce suna Kornit Digital. Tattabara printed embroidery suna tambayi kuma cikin rubutun digitalinsa daya na production line na T-shirts. Printers na direct-to-garment sa kasance aiki kwalitee don yana bincika decorations na 3D mai tsaye masu embroidery. Kuma ya tambaya a Figure 12, ya kamata yi gabatarwa bayan wannan ayyukan gaba daga stitches to prints. Mai amfani da printed embroidery ya ne ga anfani da digital control process na aiki. Ya kamata yi gabatarwa bayan wannan ayyukan gaba daga stitches to prints. A kan amfani da printed embroidery, ya ne ga anfani da digital control process na aiki. An zama duburun rayuwar fabric, ya ne ga anfani da digital control process na aiki.

Indaunan Textile 4.0

Indaunan kaiwas ta fiye a cikin gaba duniya wanda kuma suna ne a matsayin biyu na fasalin jiharai da ke nuna aiki a cikin yanzu. Suna ne aiki don labarar teknoloji, innowashiyan kibunin Industry 4.0 suna ne a cikin rubutuwa digital. Wani aimakonan ne ya yi amfani da alamun wanda ya samu da alamun wanda ya samu da shugaban virtual tabbata system cyberphysical da ya samu da humans da masina tabbata Internet of Things (IoT)9. Kana daidai ya kawo mai aiki daidai suka zama aiki a cikin wata rana da ya tambaya taimaka aiki a cikin wasu lokaci remote making kaiwarsu smart. Alamar teknoloji ne IoT da network interoperable. Daga cikin wannan, aimakonan ne ya yi amfani da produktin aiki da productivity. Don haka ITMA 2023 ya bukatar, Industry 4.0 ya ne amfani da sabon rayuwar teknoloji don wasu sharika kaiwas. A cikin tunani Industry 4.0, wasu masu cuttin da sewing machine.

wakilanci daidai a cikin samar daidai, ake yi aiki na kewaye daidai suna gaba. Suna daidai ne a ITMA. Zünd Systemtechnik ya kasance da Mind Technology da idanin Portugal ta karatun shugaban wadannan su. Juki ya kasance daidai a cikin samar daidai suka zama daga system network, an yi shi JaNets1. Mammut ya fiye shugabinsuwa sabon rayuwar software an yi shi a bincika masani aiki, an formular rubutu analytic reports ga masalaci aiki da an sani maintenance predictive. ACG Kinna Automatic ya yi aiki na kawaye daidai na karatu su suka gabata wannan suka gabata pattern matching accuracy, amma suka gabata da idanin fabric defects.

Daga wannan suna, teknolojumar kafa na duniya yanzu ake samun cikin shirin tunani da ke fiye hanyar machine learning da artificial intelligence. Kawai daya, systemar shirin tunani bai ya sosai bai ne da ke samun abokan machine dai dai ake yi wata daidai aiki da rubutun product. A cikin aiki na jinsu, suna rubutun mai sa'adon jinsu yana gaskiya kuma baya tabbatarwa suka zama gabatarwa ga wannan suna da aka sami amfani da product ya kamata user. Babban da ke samun wannan hanyar vision technology, artificial intelligence yana soya abokan tunani da aka samun wajen bayanin data da aka samun tambayoyin aiki. A ITMA, Serkon Tekstil Makina yana kasance wannan systemai tunani fabric ake samun hanyar deep vision technology da artificial intelligence. Systemai yana kasance a samun tambayoyin buga na surface, kuma aikin rubutun warnakin lissafi.

Kasa daidai gaba daga aka taimaka ne yadda alamannan suna aiki na idon jihar rubutu. A cikin shirin kwayoyin alamannan suna aiki na idon jihar rubutu (CAD) wanda suka gabatarwa, suna CAD halita ya yi rubutun digital mai tsawaccen a matsayi data bankar daidai daga samarun abubuwan daidai kuma ya biya suggetaran professional don rubutun hanyar daidai. Haka ya fadi karatu daidai a kan rubutun daidai kamar rubutun, kamar ba suke amfani da rubutun kasancewar daidai. Suna start-up company, Myth.AI, ya kawo alamannan suna aiki na idon jihar rubutu don bayyana options daidai mai tsawace daidai don rubutun hanyar daidai daga clicks daidai.

A cikin hanyar daidai, wata fayyadi na biyu — Industry 5.0 — ya kawo daga cikin aikin kushewa, don gaba suna suka ne a cikin aikin 4.0. Babban yadda nan European Union9, Industry 5.0 ya yi amfani da watsalar da aka gabatar da sabunta aikin. A kanan da aka samun wannan, aka soje daidai da amfani da sabunta mai shirye, aka yi amfani da sabunta mai jama'a. Kuma aka yi amfani da takardun fitowa da amfani da masu kebba aikin aikin 4.0. Wannan amfani bane amfani da aka zama, dominan. Amfani da idon, samari, da amfani da gabatar (ESG) ko amfani da uwar uku da sabunta da gabatar aka yi amfani da aka samun daidai a cikin hanyar daidai da aka zo a cikin wadannan hanyar daidai a dunya. Industry 5.0 ya yi amfani da aka samun daidai da sabunta mai kebba, fitowa, da sabunta mai jama'a aikin kushewa da aikin babbar riga. A kanan da aka samun Industry 5.0, wannan amfani da aka yi amfani da masu kebba aikin aikin ma'ana da amfani da aka yi amfani da aka samun daidai a cikin ITMAs.

Hanyar Fafanin

Sunan takarda teknoloji a cikin ITMA 2023 yana rubutuwa don suna hanyar automation da a cikin rubutuwa cut-and-sew a cikin babban zuciya. Sunan takarda ne binciken daga kwalite ta fi makiya. Suna na farko application na automated cutting and sewing technology bata ITMA 2019. Sunan gaskiya a cikin rubutuwa cut yana samun samun integration na equipment abubuwa da a cika wannan rubutuwa, popularity of optical pattern matching system, da kewaye heavy-duty cutting capability. Kamar wannan, sewing automation yana samun active development of core technologies, ya ke yi shi a kan rubutuwan product a kan automated configurations. Hanyar wannan journey yana samun samun dai dai domin suna zai iya samun progress a cikin industry 4.0 daga yawanci domin fourth industry revolution.

Rukune

1. Suh, M. (2019). Kattare da kewaye mai tsarin aikin 4.0 a ITMA 2019. Journal of Textile and Apparel, Technology and Management. Lissafi Mai Tsarin, 1-13.

2. Aeppel, T. (2022). Robootti ne yi shirin gaba: kewaye jeans, Reuters, Rubutu July 2023 dari https://www.reuters.com/technology/robots-set-their-sights-new-job-sewing-blue-jeans-2022-12-12/.

3. Davies, G. (2021). Ana rubuta manufacturing mai taimaka na cikin brandar fashion? Techpacker, Rubutu July 2023 dari https://techpacker.com/blog/design/fashion-on-demand-manufacturing/.

4. Li, R., Zhao, S., da Yang, B. (2023). Ikiya na bayanin tsarin machine vision technology a cikin processin furniture manufacturing. Applied Sciences, 13(4), 1-14.

5. Francis, S. (2019), SoftWear Automation ya kawo Sewbots adidi a cikin wasa, Robotics and Automation News, Fara July 2023 daga https://roboticsand automationnews.com/2019/02/05/softwear-automat ion-launches-sewbots-as-a-service/20847/#:~: text=For%20a%20monthly%20fee%20starting,and%20three%20shifts%20a%20day.

6. Textile World (2019). Sewbots® Ya Karfe Kwayoyin Karkashin Suna, Textile World, Fara July 2023 daga https://www.textileworld.com/textile-world/2019/07/sewbots-transforming-the-sewn-products-industry/

7. Hayes, S. da McLoughlin, J. (2015). Sunan suna, Daga J. Jones da G.K. Stylios (Mai karfe) Joining Textiles (pp. 66-122). Sawston, United Kingdom: Woodhead Publishing.

8. Sarkar, J., Rifat, N. M., Sakib-Uz-Zaman, M., Al Faruque, M. A., da Prottoy, Z. H. (2023). Tehnik Advanced a Cikin Sunan Lissafi. Daga M. Rahman, M. Mashud, da M. Rahman (Mai karfe) Advanced Technology in Textiles: Fibre to Apparel (pp. 177-231). Singapore: Springer Nature.

9. Muller, J. (2021). Tsauni Na'enƙi Daga Ciwon Industry 5.0, European Commission, Yanzu July 2023 a https:⁄⁄op.europa.eu⁄en⁄publication-detail⁄-⁄pub-lication⁄8e5de100-2a1c-11eb-9d7e-01aa75 ed71a1⁄language-en.

Rubutun Editor: Dr. Minyoung Suh yana daidaita kwayoyin Wilson College of Textiles a NC State, Raleigh, N.C., a itacewa Textile and Apparel, Technology and Management. Rubutun na yi ayyukanan suna a Textile World daga rubutu na Dr. Suh a jurnalina NC State Wilson College of Textiles’ Journal of Textile and Apparel, Technology and Management (JTATM).

Janarai⁄Fifiruwar 2024