efficient computerized embroidery machine

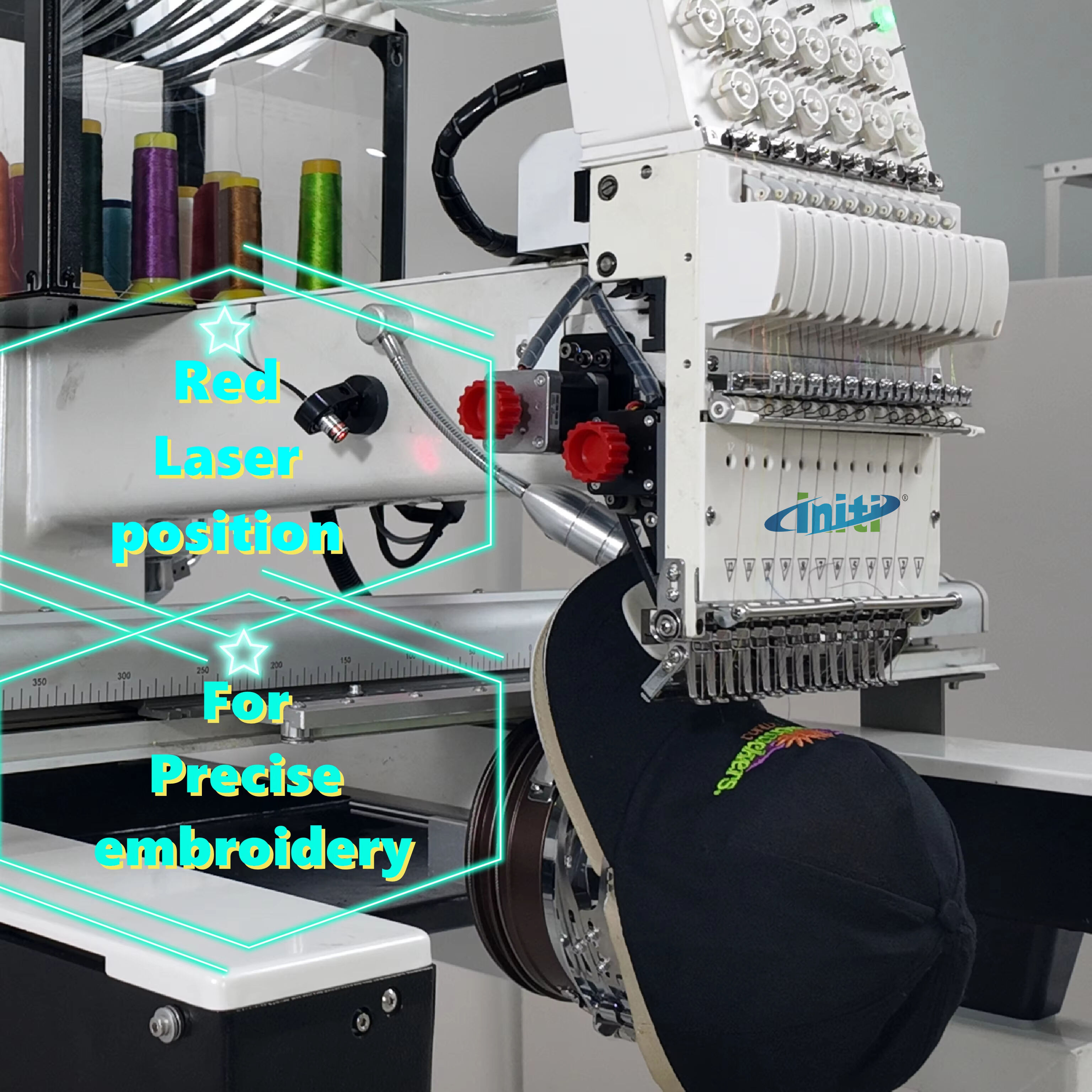

The efficient computerized embroidery machine represents a significant advancement in textile manufacturing technology, combining precision engineering with digital innovation. This sophisticated equipment features a high-resolution touch screen interface that allows users to easily select, modify, and execute complex embroidery patterns with remarkable accuracy. The machine incorporates multiple needle heads, enabling simultaneous embroidery with different colored threads, significantly reducing production time. Its advanced threading system automatically detects thread breaks and maintains optimal tension throughout the embroidery process. The machine's memory can store thousands of design patterns, and it supports various file formats for easy pattern importing. Built-in sensors monitor fabric tension and automatically adjust settings to prevent material damage. The machine's frame is constructed from industrial-grade materials, ensuring stability during high-speed operations of up to 1,200 stitches per minute. It accommodates various fabric types and thicknesses, from delicate silk to heavy denim, making it versatile for different applications. The automated color-changing mechanism eliminates the need for manual thread switching, while the precision positioning system ensures perfect pattern alignment every time.