embroidery machine manufacturers

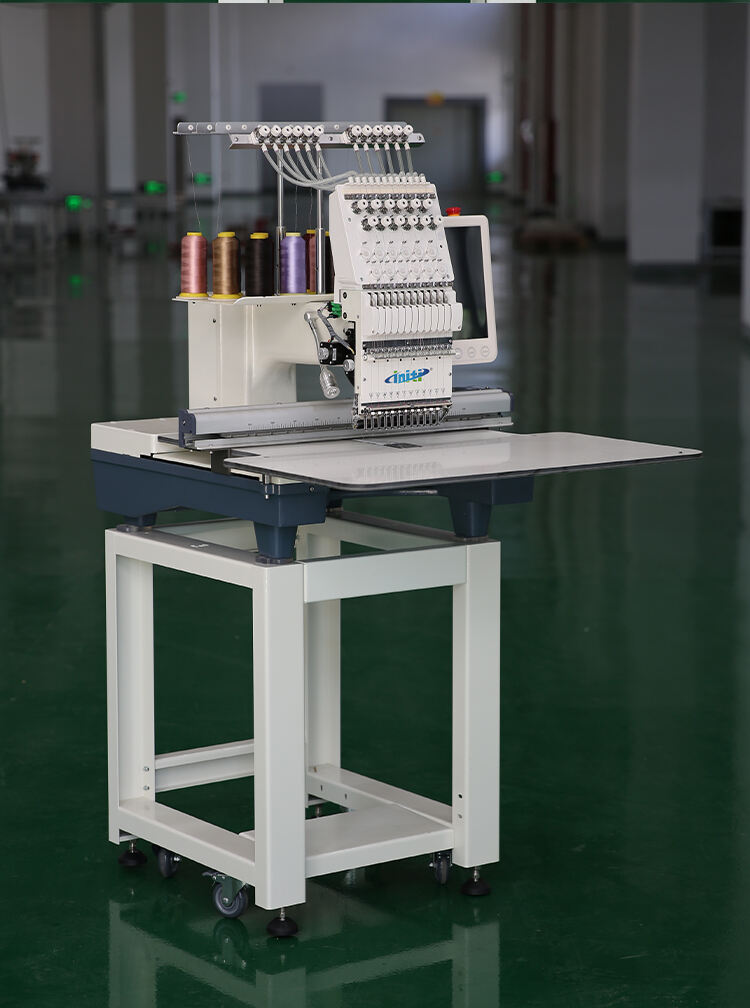

Embroidery machine manufacturers stand at the forefront of textile innovation, producing sophisticated equipment that transforms plain fabrics into intricate works of art. These manufacturers develop machines ranging from compact single-head units to industrial-scale multi-head systems, incorporating cutting-edge technology such as computerized design interfaces, automated thread handling, and precision control systems. Modern embroidery machines feature advanced capabilities including automatic color changing, thread trimming, and pattern recognition, enabling seamless production of complex designs. These manufacturers prioritize user-friendly interfaces with touch-screen controls and intuitive software that allows for easy design creation and modification. Their machines typically offer multiple embroidery field sizes, various hooping options, and compatibility with different fabric types, from delicate silk to sturdy denim. Many manufacturers also integrate IoT capabilities for remote monitoring and maintenance, ensuring optimal performance and minimizing downtime. The machines are engineered to maintain consistent stitch quality at high speeds, with some models capable of producing up to 1,200 stitches per minute while maintaining precise tension control and pattern accuracy.