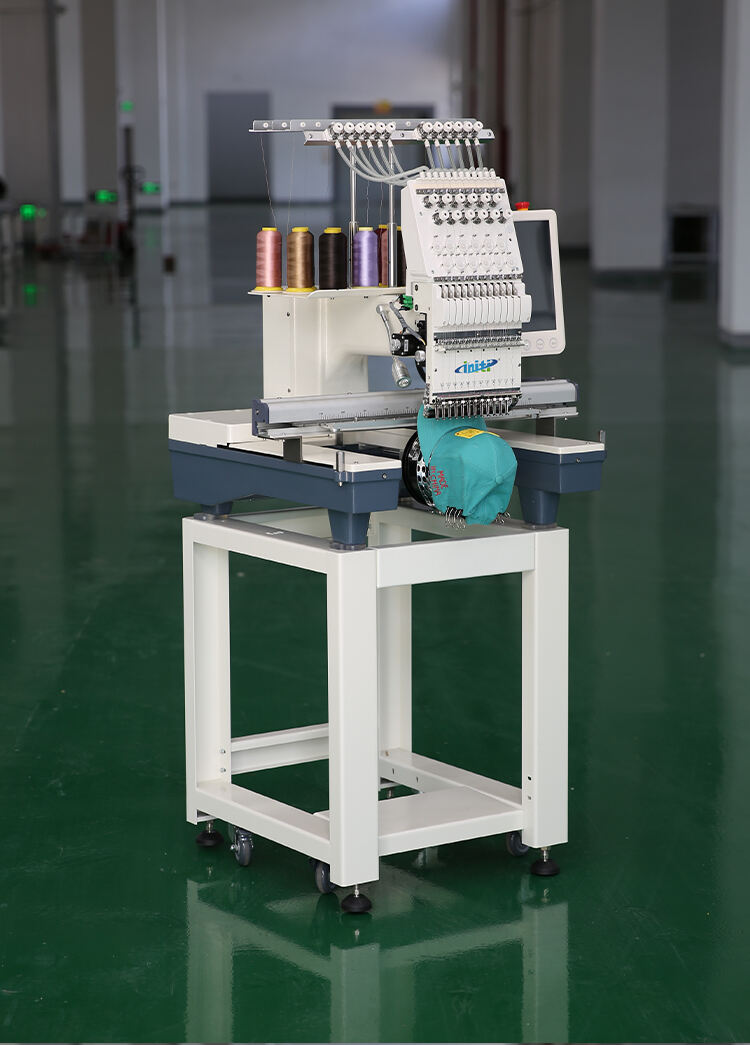

safe embroidery machine

The safe embroidery machine represents a significant advancement in textile manufacturing technology, combining precision craftsmanship with enhanced safety features. This innovative machine incorporates multiple safety mechanisms, including automatic thread break detection, emergency stop functions, and protective needle guards, ensuring operator security without compromising performance. The machine features a user-friendly interface with a large LCD touchscreen display that enables easy pattern selection and customization. Its advanced servo motor system provides smooth operation while maintaining consistent stitch quality across various fabric types. The machine's ergonomic design includes LED lighting for improved visibility and an adjustable work surface for optimal comfort during extended use. With multiple needle capabilities, the safe embroidery machine can handle complex designs and accommodate different thread colors simultaneously. The built-in memory system can store thousands of designs, while USB connectivity allows for easy pattern transfer and updates. The machine's frame is constructed from industrial-grade materials, ensuring durability and stability during operation, while specialized sensors monitor operational parameters to prevent mechanical issues and maintain safety standards.