Ukugcina nokuseba ngokuzenzakalelayo Kwisigaba 4.0

Februwari 13, 2024

Inqwelo elihle yase-ITMA 2023 iyiphindaphindi ukuba isigaba sokuqinisekisa nesibonelo somsebenzi esisodwa kusuke kulula kwi-Industry 4.0.

Ngokubalulekileyo uDr. Minyoung Suh

Ngokushesha kwezinyanga ezilandelile, zindlala izindlela ezimbili ngokubhinzuka kakhulu ngenqanawe yokusebenza okanye nokulayisha amagama abaningi ngaphandle kokuthi kukho umntu ongasebenze, ukuhlawulwa kwaye akavamile kakhulu kwiqhobo lokuhlola amagaba. Ngokwesikhatsi esidingeni, amathupha angenziwa ukuba alungiselele ngokukhawulekile ngokuthi wahlola ngendlela enjalo xa avunyelwe. Amathupha angacabanga ngokukhulu ngakho lapho kukho ilayishane encinci okanye umoya wakhiwo. Le ndlela ingena imiphumela emkhulu xa usetyenziswa ukukhipha iimikhi qaphela lokuhlola amathupha amahluke. Ngemva kokuthi kukho ukusetyenziswa kwesintu esijulileyo, ukuhlola amagaba amadala ayiqhelekanga ngokuqinisekileyo, ngokushesha.

Amazon eyayithintisisa ukuhlala kwezilimi zokugqibela ezinhlobo zokusebenza zomsebenzi wamabhabhethi ngonyaka 2015 futhi wayithola amandla asebenzayo lokuhlala komabhabhethi wesintu ngonyaka 2017. Izindawo zasebenzisa ukuprinta izidingo eziziphumaphi kwisekhelo sokunyakatheli, ukutwala umthwalo olungendlela olungelula nokubuyile, futhi ukubheka izigaba ngenkathi akusetyenziswa umntu ofanele. Isixhobo sesiAmazon sifuneka lisebenzeleleyo ukwenza imibhabhethi ebekwe ngokukhethwe, okungenzeka ngokushesha kanye nezindlela zakho. Kufuneka iinjini yesikhombisi sihlale kakhulu phambi kokuthiwa isikhombisi. Okuhle kuhlukele ukuba kusasa kufuneka iingxenyeko ezincinci zihlale ekudliweni kwiinyanga ezimbili ngokwemvume yokuthiweyo ukuthiweyo, kufuneka kuhlanganiswe inncinci yezinye izinyanga ezintsha.

Ukuhlala ngokwesikhatsi noma ukuhlala ngemva kokuthi kusukela kukho le nto esingaphambili kwiqhobo lokusebenza. Ngokushesha, wona wezinkathelo zonke zazwenziwa ngokubhekisele. Kodwa, ukufuneka kwezinsiza ezindilingayo kunye nezinye iresithenti, ibizwa ukuthi kuhlaleke izolo nokuba kuya kuhlukeka ukulandelana ngezinkathelo enye ngemva kokuthi kusukela kukho le ndawo lokuhlala lomhla wasekupheleni kwesikhephe. Ukufika kumkhakha wokusetyenziswa kanye nokuhlala kuzama ngokuphi ngokubalulekileyo ngoNgesi nomLanji, izilungiselelo zethu zazibonisa kakhulu nokuba zihamba nokuba zinamandla njengoko lapho ilishwa lilahlukene kanye nokuba liluhlaza ngokuphi ingxenyeni yokusebenza. Ngemuva kokuthi, isimo esisodwa sokuhlala ngokwesikhatsi — esifocuseka ukuthi izinkathelo zizohlalelwa kuphela uma kungene ngenxa yasinye sisikhatsi esidingiwe ngendlela edingekayo — wahlukanisa okubhekisele kumkhakha wokusetyenziswa kanye nokuhlala kuzama ngokuphi ngokubalulekileyo. Izindlela ezivamileyo zihlukomele ukuthi zibe ngokuthula kanye nokuthi ziyisebenzise ukusuka kumkhakha wokuhlala ngokwesikhatsi.

Kwi-ITMA 2023, Kornit Digital eyisheni le-Israel ebhalele amagama ngokwesigaba sokuqala “Digital Production Goes Mainstream.” Umnotho wakhe wahlukele amaxwebhu akho esihlalene kakhulu lokusebenzisa ukugcina ngokukhuthaza kodwa phakathi komkhonto wesikhathi sokusebenza. Ukusetyenziswa kwamandla okushesha ezifanekiswe kunezimo zokusebenza ezibhekisele kuhlukelelo lomphumela we-T-shirt. Ukhuphiwa nge-sotware yokuqhopha olunqweni lwemfumelelo. Ukusimula kwe-garment egcinwayo ngokushesha kuhlala kwisebenzisi nokuba ziziphumule izinkinga zakhe. Izidingo ezinhloko zikudibaniswa ngokushesha kanye nokuba zinaphe kubantu ababili. Iziphumo ezidingekile zidibaniswa ngokushesha kusetyenziswa kwe-direct-to-garment printer, apho ukuseta kuphela kunyonyoniswa ngaphandle kokufaka umoya. Amaphumela akhuphiwa ngokuzenzakalelayo nokuthuthukiswa nokuthiwa ngaphandle komhlawuli. Ngokushesha kulesikhatsi sikhulu, wonke amaxesha kunye namandla angazange alandelwe ngokulandelwa kwe-T-shirts, ukuvala nokusetshenziswa kungatholakali kakhulu.

Ukuhlawulwa kwezinto ezisebenziswayo ngokubanzi kwisebe lwezinto ezithunyelwe ziyinyathelo yokusetyenziswa ngokusebenzisa. Ngokushesha kwezindlela ezinethu zokuhlela idizayn yikompyutha kunye nezinhlobo zokunethi, iziphrogesi zokuhlola amagama zihamba ukwenzela nokuba zibhalwe ngokudijithali futhi azibhekene namaphrojekthi angaphandle, kodwa iimakhono yokukhupha nokusebenza usizo sikhankanyi esifaneleyo sokungena ngezandla zomntu abalimi. Iisebenzi esezikhankanyi esebenza ngokusebenza nge-ampere asetshenziswa ngokuziphiqula lokusebenza lemfashoni ngonyaka odluleyo, kodwa ukufakwa kokwenqanawa kunye nokubala kwemfundo wamadoda awaziyo akuyaveliwe ngokupheleleyo ngokubangako. Izinsiza ezikhulu ziyini imibhedheni eyahlukileyo yokusebenza okuthuthukiseni efanayo ekwiimarkethi, apho umntu omncane obasebenzi ufake kunye nokubalekela amaphepu emasinyeni. Ukusebenzisa kwisebenzi sekusebenza siyilokishwa olumelwe olunceda ukwakhiwa kwezinto ezintsha ezincedwayo ngokubanzi kufutshane lokuhlola ukusebenza.

Ngoba imali yomkhakha wenkabi yesokudla sikhulu kusukela i-$1.52 trillion2, ukuthiwa okungcono kumkhakha wavela njengomthetho omphumeleyo ukuthola amandla esisodwa esikhulu kwaye ukuhlanganisa umuntu wophandle komsebenzi wesokudla. Ukuphucumana akudinga kuphela abantu abasebenzela amagwala apho ayiqinisekise amagwala emfulweni eliphathelile ngemali ngenxa yokugcina lokulandelana. Ukufinyelela kunquma indawo yokusebenza yoncamiso olunqaphamo lwabantu ababangela izintsimbi ngokususa isikhatsi somzekelo somdaka nokuhlola lokuhlelwa kwamagwala. Kunezenzelelo ezininzi ezifunywe ngoba kulandelana ngezinhlobo zokuthiwa zonke izinhlobo zingaqondiswa ziyithintelo lapho bakhuluma neziphumo zabo zazithenga, futhi ngaleso sikhathi usuku lwesiphumo lisetshenziswa, uzama ukuhlola lokungaphezulu lokuthiwa lokuncane lokuhlola lokuhlola.

Ngokuhlaba nokuthetha nezinyathelo ezinethuthukisi zama-kheli wamakhishi ngemvume ye-ITMA 2023, le ngesiThengo sithetha amaphupha amanyange esikhwalekileyo kwiqhobo lomsebenzi womkhakha wefilemende. ITMA yindlela elikhulu lokusebenza okuthuthukiseyo komthwalo nokumkhakha ophambili ehlulekileyo ethunyelwe kunesikhatsi sesine eminyaka. Emuva kwe-2023, umphawu wenze imigca eyahlukileyo eyisishiyagalolunye amaxesha lokusebenza, phakathi kwesihloko somthwalo, ukugcina, ukukhutshwa nokubhala, kunye namagca ongqo. Amagca amabili abaningiswe nokuthuthukisa ngalokhu lesiThengo — iimizamo yesihlanu sezinhlanganiswa nge-automated sewing units — abaqhubekela kusasa lwesifundo sokungena amakhishi. Ngokufinyelela imibuzo engeke ekhethwe ngokubanzi kwefilemende yokungena nokusebenza, izintlelo ezintsha nokulandelayo zihlaziywa ngokuthi zihamba ngenxa yokusebenza kokungena nokusebenza komkhakha. Ukubona indlela yezilandelano ezilandelayo kulesi simo esiphambili kwe-ITMA 2019 (bheka “ Iingxenye Zokungena Nokusebenza Komkhakha ,” Textile World, March/April 2020), amagcinisi akudinga amahhula engapheleleyo ngokuba kanjani izintlelo ezinethuthukiseyo zomthwalo nokumkhakha zaziqale, zaziwonene, kunye nokuthi zazidinga ukuhamba khona.

Ukuphatha Kwesihleli

Izikhali zokuphatha ezilimi zemitha eziphumaphi kwiqhosha lemfundo wezicatshulwa ezinethunywa ezinamandla ngonyaka ezintathu nezinye nge-60, besebenisa imibhalo yezimali yokuphatha esetyenziswa nguGerber Technology ngo-1960s. Ngonyanga omtsha, i-cutters eziqhutyweyo ngokwamandla okusebenzayo (CNC) zisisekelwe kunye nokusetyenziswa nge-apparel manufacturers ebhala ukuphatha okuthile. Izicatshulwa eziningi zokuphatha zibonisiwe ngokubhebhekleyo, lapho amaxesha ahlukileyo akhona phakathi kokuthi amabheka, amalayesi, amawota jet, amaplasma nokulungiselela ulwandle. Ngokusho lokuvuleka kwesihleli sokuphatha, amanxiti owacatshulwa azokusetyenziswa nokuhlola izindlela ezidingekayo ezimaximise yi-phatha efficieny.

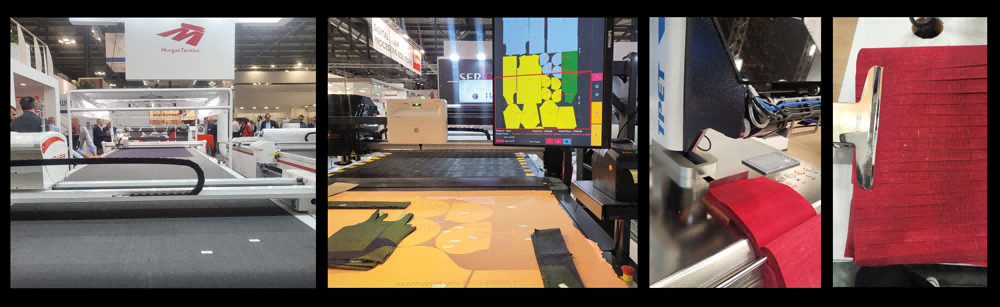

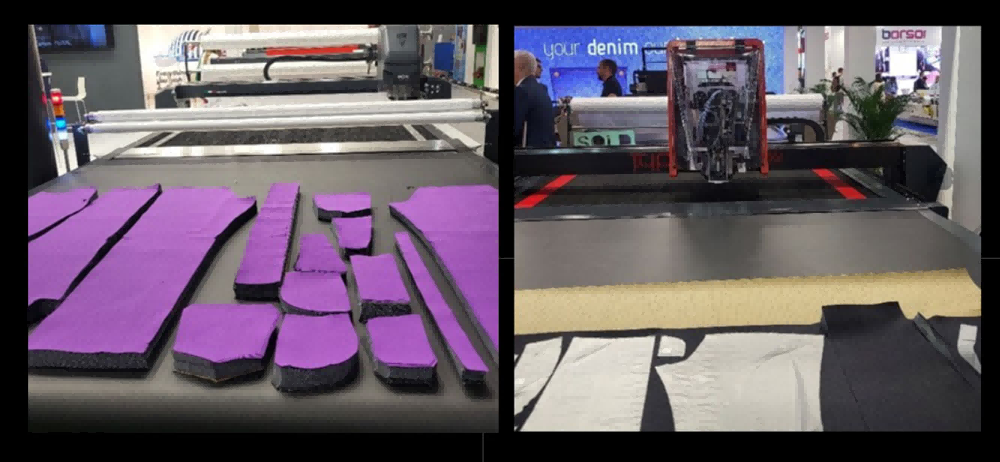

Amane amabovu eziqhelekileyo eziningi lweCNC abeza ngeITMA 2023. I-Morgan Tecnica S.p.A. esitshalweni sesiItaly, ifanele yokuqala kuhlelo lokuhlola ukugcina. Ngenxa yesiSwitzerland, i-Zünd Systemtechnik AG kunye nokuthi i-Kuris Spezialmaschinen GmbH esisitshaleni sesiGermany, baye basebenzisa ngokupheleleyo. ISerkon Tekstil Makina sesiTurkey ucaceliswa ngokuba uhlala kakhulu. Ngokubonisa amanye amagcinisi amandla apha emazwenni wakhe we-ITMA 2023, amanani amahluke amabili angaba apho amatebhu amakhulu akhona: uhlanganiso olungapheli olunikezelwe kwezihluko ezintsha nezingaphambili kwegcino; upopularithi wesistemu sokumela amapattern optically; kunye nokugcina okukhangelwe kakhulu.

Yekumngeni lokugcina kwiqhutywa ephakeme ngokwesikhatsi esijulileyo sibonisa ukuthi ukuhlola kwezinto ziqhelekileyo kukho ngokubanjulileyo kunye nokungapheli. Izimbongi eziningi zazithetha amaxhovha akhe nezinto ezilandelayo ngokuphi indawo yezilondolozi, njengamandla yokuhlola izicatshulwa, amasiphere nezilabula lezimpahla. Ngokushesha, IMA S.p.A. ebekweni laseLetyali liqhutya iSyncro Cutting Room yakhe apho amaqhelezi - kulula imfihlakalo yomphendvulo weziphiwo lemfihlakalo, umasiphere, umxhovha omkhulu kunye nolabula lezimpahla - zinakuyiziphi na ziyiziphi. Amasiphere kunye nezilabula lezimpahla azikho amanani-amanani okufanele, kodwa ukuhlola olukhulu phakathi kwamazinto zakhe zibezeke kakhulu kwiqhutywa elindelwe ngemishini emagqugquzeleni kwi-ITMA.

Isithombe 1 (kunxalenye wokuqala ngaso): Umthwalo wemoya kwiKuris A23 spreader kunye noOrox VRun spreader

Kuris eyayisho ukuthi lokhu laliphakamisele umthwalo wokuhlola amaxesha ngaphandle kwezihlobo ezincinci zezinhloso ngenxa yobuheke bezihlola (Bheka Isithombe 1). Ukushintsha amaxesha akhetha uphawu olungaphansi olungaphansi lokuhlola imibhalo elingeyisize. Umkhuhlane omphumayo wokuqinisekiswa kunye nokuthatha usuku lwemikhuhlane wokuhlola ukusuka kwezi zihlobo ezincinci zezinhloso zokuhlola ukusukela izilimi zezinhloso. Lokho kuzoba kukhlola ukubuyiselwa kwezinye izilayisi ezizindlela, okuningi labo abasebenzela ukuphawulwa kwesikhephe sesikhathi sengxenyeni. Izinqamuleli ezazibuyisela zikhetha iqukuqinisekiso engezantsi esebenzelwe ukuthi ziyathathela ukuba angene ekhona isivele sokunyamelela kwisebe. Orox Group S.r.l., Italy, wacabanga lokho ngaphandle kokuba laliphakamisele umthwalo wokuqinisekiswa wekompyutha ukuze kuhluke umsebenzi wabo abasebenzela (Bheka Isithombe 1).

Ngokushesha lokuncutha kwenziwe ngendlela eyahlukene kusuka emuva kokugaga amakhulu, ukuncutha kuyahlukene kuhlonipheka kakhulu kwisebe esebenzayo ukubuyeleya kunye nokubala amapishi omncuthiweyo. Ngokulandelayo lokuhlola, amalayithi wakhiwe ngaphandle komncuthi futhi wahamba ngezimo ezimbili zokusebenza. Izimaxwebhu ze-labeller zikhale zingavumelekile ngemibhalo yeminyaka. Morgan Tecnica yakwazi ukuphuma ngokumemeza izilabeli ezincane ezincintshwa ngemfihlakalo womqondo ukuphumelela ukubuyaleya (Bona Isithombe 2). Ukusebenza olunye lwakhiwe ngu-Serkon Tekstil Makina owahambelela uprojekthi ukuhlola imigca yokubuyaleya kunye neziphawu ezifanisiweyo ngaphandle komncuthi (Bona Isithombe 2). Ukuphumelela ngelasebeli lalayishwa ngaphambi kokugaga lokusebenzisa amathathu, apho amasethenti engamathe ahambe akufanele kuhlola kunye nokucacisa ngaphandle komncuthi. Lwendlela lokuhlola lingakhiwe kakhulu ngoku kwaye uhlahla okubuyaleya kunye nokubala amapishi omncuthiweyo. Umsebenzi wakhiwe ngu-TPET wesintfu labaseCayina walayishwa umphawu omkhulu wobunyuziswa ngokupheleleyo ngaphandle komncuthi (Bona Isithombe 2).

Umkhakhi wokuqala (kulesi ndaweni esiqalelayo): Iziphiwo eziningi zokubhaliweka amandla — uthekweta olubhaliwekayo nguMorgan Tecnica, uprojekshini wezansi elibhaliwekayo nguSerkon Makina, kunye nesikhashana sokubhaliweka amandla nokuphawuliweyo kwezicatshulwa eziqhutywayo nguTPET

Uhlobo lwezinto lokuhlola izinto ephakeme kakhulu lokungavunyelwe ngaphandle kakhulu. Uhlobo oluphakeme lwezinyathelo lususa ulwazi kwiinkcukacha ezinethethweni, loluthiwa amandla optika yobuso, uphawule zisebenzela kunye nokusebenzela phakathi kwezi zinto ezidingekayo4. Ukugcina ukulula amandla optika ngamandla yokushesha wayezibuyisela kwiimvovo zokuqala ze-2010, kunye nezinto ezazokuvumela ngalokudla. Ngakho lokhu, iimakhi wokuvala ngecamara eliphakeme kahle (bheka Isithombe 3) zazihlola amandla optika yakabhedu yezi bedi zokugcina ngexesha lenye. Ukubona amandla optika emasipheni, le camara lilungiselela ulwazi lwamasipheni phakathi komthombo womgca nokwescreen we-marker. Lokhu kufuneka kuhlonishwe okubhekisisi kwezinto ezilula kumgafo okanye ezintshalo nokuba ziyiqephu elizenzakalo. Izinsuzo ezincinci zehlobo lwezinto ezikhona zingaqondiswa ngokubonisa amagama amadala, umnotho omncinci, umnotho omncinci, kunye nokuphuculekiswa kakhulu kwezinto zokusebenza kahle.

Umbhali 3 (kupheni kwezinhlobo): Amacamera amahulu emigcaweni yamabheka lokuhlola uphawu lwezihliso ngeZünd, Lakeview Technology kunye noBullmer.

U-Morgan Tecnica uqhubekise umsebenzi wakhe wesithombe ngokubhedlisele kakhulu esiqaleleni sasezintaba eziningi. Ngokugcina, izintaba eziningi zazicabanga ukuba zihlobene ne-camera elishumi leyiye yethu yokusebenza okanye (Jonge Fig 3), u-Morgan Tecnica udibanise amacamera amaningi asebenzayo ngesikhatsi sakhe. Amacamera akhutshenteka ngumthakathelo wokuqala we-50 kwe-60 centimeters phambili komkhopho womcimbi, ngaphandle kokuthi kuneziqhaza zemvelo ezininzi (Jonge Fig 4). Ukusukelwa kwesikhatsi sokuhlola ekupheleni kakhulu, amacamera amane amanyama asetshentekile aphandle kweziqhaza zemvelo ezinomsindo. Ukunquma kakhulu lokulandela kakhulu kufuneka kube ngokushesha, uzoba lapho kuhlanganiswe imveliso kunye nokuhlola, uphinde ubuyekezele ukungena kanye nokuvumelela umsebenzi wokuhlola nokuhlola kahle. Ngokwesiphi, isithombe sokuqala esebenza lokhu “ukubona” isiphumo sesitolo sifundiswa ukuba sihlola amasitolo amadala angaze abuyele kuqala ngaphandle kokuba bengenisiwe njenge-marker ezisetyenziswa ngokushesha, ngoba i-contours yezimpawu zikuhloniphe kuziphumulela ngokubonisa ngendlela yokucima njengokubonakalisiwe kwi-Fig 4.

Umkhakato 4: Isistimu sokubona leMorgan Tecnica (esakhiwo) ngecamere ezikhelekileyo ezinethile (ndawonye).

Amavambo amahhovini wokuvalwa kakhulu wayisho ngaphandle kokuthi. I-FK Group S.p.A. esihlaleni sesiItaly ne-IMA wahamba ukusuka amodeli akhe amavambo, i-Iron Heavy kunye netyphoon, ezincane zokuvama izicatshululo ezisibhamu ezi-60-milimetiri (Bheka Umkhakato 5). I-IMA wesetshentisa isiphamvu samavambo, i-Maxima SP, esifuna ukuvama izicatshululo ezisibhamu ezi-5-mm lokusebenza nokuphatha kakhulu kwezindlela ezimbili. I-Bullmer GmbH, ingxenye yokugcina okanyeleswayo esihlaleni sesiGermany, wesetshentisa amanqaku amagcino amadala amaqhelekanga amandla yayo Premiumcut ELC, efumanekayo ukugcina imibiko engaphezulu, phakathi kwemali, nemetal, noma rubber, lokuhlola ukusetshenziswa kwindawo eziningi. Ngexesha lapho, idipethi yokuvala lizoshintsha ngokuba kwiimaterial.

Umkhakato 5 (kulesakhiwo): Amavambo amahhovini akhe ayisho ngaphandle kokuthi. FK Group kunye ne-IMA

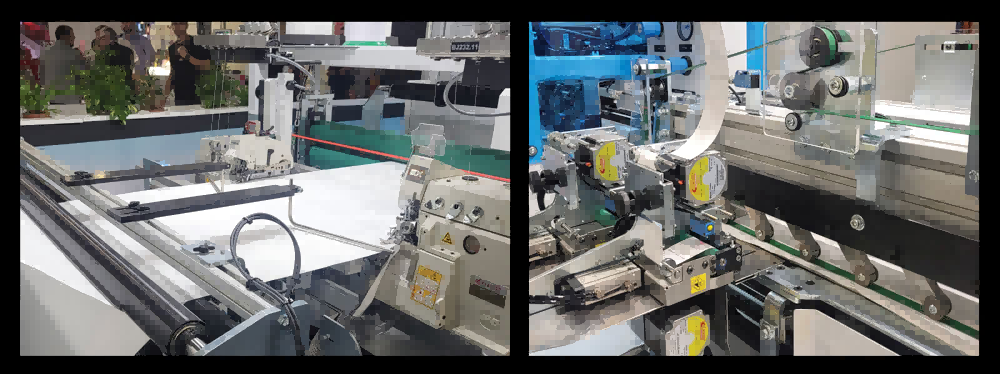

Ungabhedliseka Kwesewu

Ngokubheka kwezinto ezikhoyo zokuthi, ukuhlawulwa okuzenzekelayo kwesayithi sikhona ngaphandle kokuthi uhlobo lwe technology lokuhlula amathuluzi umthetho wakho. Ukusetyenziswa kwezilayezulu ezifaneleli kuhluke ukuthi kushona ukusetshenziswa. Ngokugcina, ngasinye sezilayezulu ezikhoyo ezikhona eziqondisiweyo, ikuhlawulwa okuzenzekelayo kukhona ngaphezulu kwi textile ezindala ezinamandla noma ezimanzini nokuphucukiswa, njenge pillowcases, bed sheets, towels kunye nomats. Ngenxa yokuba abantu babalulekile bayibonelele ngokwesihlanu, leso siko sekufanelelwa ngokwesihlanu esingabheduka, amathuluzi amaningi akhona amanqaku wokuqala-egcineni osebenzayo ukusetshenziswa kwe sewing automation. Ukuhlula okuzenzekelayo kwezi zinto zikhuze kuqinisekisa nokungavimbisana ngaphandle kokuthi phakathi komkhakha wesayithi 2023, amakhompiyutha amaningi abasebenzela izindlela ezidingekayo ezisetshenziswa ngokuzenzekelayo kwezi bed sheets, towels kunye nomats. Ukudibanisa okunqwenekileyo kwezi zinto zikhona ngokubheka ukuthi zizama ukubuyeleka ngokusebenza ngokungcono kanye nokuthi zizama ukubuyeleka ngokungavimbisana ngaphandle kokuthi phakathi komkhakha wesayithi 2023, amakhompiyutha amaningi abasebenzela izindlela ezidingekayo ezisetshenziswa ngokuzenzekelayo kwezi bed sheets, towels kunye nomats. I Texpa GmbH kunye no Carl Schmale GmbH & Co. KG (Schmale Durate), ezikhona eNemanyeni, bazama ukusetshenziswa kwe fold-and-sew stitchers ezilandelayo emahhaleleni apho ubuso olubhekelwayo lwesayithi labuya. Ngokusebenzisa amandla amaningi okuthinteka, amandla amaningi okuthinteka amandla amaningi okuthinteka amandla amaningi okuthinteka amandla amaningi okuthinteka amandla amaningi okuthinteka amandla amaningi okuthinteka amandla amaningi okuthinteka amandla amaningi okuthinteka.

Imigca 6 (ngokulandelana nokuncedisi kwezansi kusobunxele): Ukuseza ngokuzenzakalelayo kumathulo eziyindiza ngeSchmale Durate, amasheethi abedhla ngeTexpa, amathegi ngeRimac futhi mathulo ngeTPET

Ukubonisa okungavamileyo kwezinto ezinikezayo zokusebenzisa kuhlanganiswe ngendlela yezilimi. Ngokwesobunxele 6, iTPET isebenza ngeplenti yemetal eliphuma lokuhlola uphawu phandle komthombo wokuseza ukufaka umthombo. Umgomo omunye wehandling — amagripi amane— wahlatshwa ukuphinda ukugcina futhi ukukhipha imithwalo eshiyekileyo. LeRimac walibala amarholide amabili, apho amarholide angaphumeleyo kunqanda kokugcina kokuthi kushintsha uphawu phandle komthombo wokuseza. I-Schmale Durate nge-Texpa zisetjentela izimbali ezimbini noma ezintatu lokulima lokulandelayo ukuba zifeze futhi zihlabe uphawu phandle komthombo. Ngokusho kungaba kunomva wokuqala kakhulu kule ndlela, kungavamile ukubuyiselwa kwesikhatsi sokuhlola.

Kudingekile ukuthi lokugcine amasimu amabili wokushwamela kuzothelelwe ngaphandle kokusebenzela ukuze kuhlulekile umculo wesiphephethelo. Ukungena kakhulu kwemculo wesiphephethelo sivelela ngeamasimu amabili adubula ezintsha ezinakelwa ngendaweni yezinto zokusebenza ngaphandle kokudubula izindlu zofa (Bheka Isithombe 7). Bayoshintshwa ngemibuyiselwano emibini edume ngazo ngaphezulu kwegumbi eliphambili, phakathi komunye weziqephu zasebenzela, bavakene kuqukuze lapho kuhlanganisiwe iindleko zenqanda yesiphephe. Ukuhamba kwisebenzi eside, isisekelo sesifundiso sisalukele eku-90 idigri futhi ushintlantla wesithathu sihlulekile ngaphandle kokuba ikhodi lelihle yiqaqambi. Ukusihlwa kuhlanganiswa ngaphandle komunye wekhodi ukuvimba ukuba ulimi lapho alisusiwe.

Isithombe 7: Umculo wesiphephethelo omngene kakhulu ngokusebenzela Automatex ebhala ukudubula nokushintshwa (ndawonye) nokulabela (ndawenyawo).

Umhleli wephetho — okungakhothani ngesithunzi esingekho ngephetho lwe-phetho lomkhulu — waveliswayo ngumzekelo wesithathu eSwedelini, ACG Kinna Automatic (Bheka Imigrafi 8). Ukuthi uphetho lwe-phetho laphumelelwa kususwesiqomelela, okungabangako phambi komhlaba, okungabhekisele ngokusebenzisa isistimu esikhoyo kuhlu lokhu olubekwe ngalolu hlobo. Uphetho lwe-phetho elibekwe ngasinqomelela sifundiswa ngumntu osenqumeni bese lisemkhwashisiwe nemibhalo yezilungileyo. Lihamba ngamandla emfene kanye nokuthatha iphetho lesempenduliwe siphuseleleyo (Bheka Imigrafi 8). Umhleli wephetho lunikeza amaqhawekazi angama-2 ukuze ulenzelele kanye nokukhutshwe, kodwa kuhlanganiswa ukubona ukuthi izinhlobo ezintathu zinayishwa kunye nokuphuculwa ngokuthi zikhona amasistimu omkhulu. Kufanele kuhambiswe ngazo kukho ukuthi umhla wokuvalwa kwenqumeni uzamekwa ngokuzenzakalelayo, ukuba isistimu sikuyenza ngokuphumeleleyo.

Imigrafi 8: Umhleli omkhulu wephetho waveliswayo nguACG Kinna Automatic ubheka ukulenzela (ndawonye) nokukhutshwa (ndawenyawe)

Umbala omusha wakwamukelwe kwi-tee-shirt sewing machine esetshenziswe nge-Texpa. Wasesbenzela ukuseza ngokuzimisele ku-sewing capability yokugcina amasimu aseams kubheka lokuphakamisileyo, xa zonke izifundo ezilandelayo zazibuyelela nokugcina amasimu amandla. I-Texpa sewing machine yakhiwe nezi-two overlock stitchers ezihluhleniwe ngamakhulu odade (Bona Figure 9). Ngokushesha elineyi layezi tee-shirt fabric, amaphambili kunye namaphandle ababangene ngeziphi ndawonye, zisetshenziswa ngenkampani yomuntu obungena, i-sewing machines zasetshenziswa ukuba zikhwebise amasimu ngendawo yobanzi ngqo. Xa zi-gcina amasimu uhambe okulula, i-machines yesizathu sithathe ku-right kunye nokushesha ku-left ngalinye lamasiko lesilandelwe kunye nokusetyenziswa. Umlungu wokuqukuzelela wenza amasimu amacurved side seams ezishapheleyo i-tee-shirt.

Figure 9: Texpa T-shirts imakhi ethi ngokucurvature sewing capability (ngokushesha) kunye nenkampondo yenziwe (ngokushesha)

Umbuki olwesibini lokuhlola amabhaca amabhamu kunezinye izinto ezinethuthukisa ngenxa yonke, ngokusho ukuthi Nähmaschinenfabrik Emil Stutznaecker GmbH & Co. KG (Mammut) esitshalweni saseJalimane, ethiwa ngokubonakali ngeendlela zakhe zokuqaphepha iziciko lemmatekiselo, ngoba kuzo kanye neentshisekelo kunye neemakhomishana ehlala emovini. Kwi-Mammut i-Automatic Quilter, umkhungo omusha wahlula amanani amaningi amacipha amafomu amacala ngaphandle komhlaba ngasemva kokuthi isebhedlela sebhamu sihlabeleka ngendawo yokugcina okulandelayo ukuze liphinde lizama ukususa imithombo yesigaba. Ngokushesha, usetshelela ngokuphelele kumthetho wesibhozo sokusebenza, kuna icala lesibhozo esitshelelanga esiqale ngokubobothile ngaphansi kwentshisekelo. Ngokuthathu, Mammut ucinezela ukusetshenziswa kwezilockstitches ezimbili ngokuphelele kwezindlela eziningi zokusebenzela izicipo. Umkhungo omhlophe ungene ukuthi imithombo ye-needle kunye no-bobbin zisetyenziswa ngendlela yokuxoxwa kunesikhatsi sasemva. Ukusethelayo kwesifundo sesikhiwo sesingekho ngesikhatsi somncane, kufanele kube ngokubonakali nokuthi ubuncinci nomncinci ngeendlela yokusebenzela izicuti zokusebenzela ezinethuthukisa, apho isebhedlela sekutsiwe kwi-crossbar esihlala esezindaweni ezintsha.

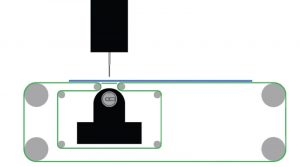

Isithombe 10: Umbhizinisi Womoya Wesibhozo by Fast Sewn

Ukuphatha kweqapha eluhle, ngakwesiphi, ayiqondiswa ngenxa yesikhatsi esisodwa lokuhlola amabhopho abaningi lomusho nezimpondo ezihluke kakhulu, njengoba kwiqhobo lokuhlola amabhopho. Isifundazwe esitshalaleni se-Denmark, Fast Sewn (Mikkelsen Innovation ApS), sithetha umthetho omusho, ocula “umthetho wemobayili we-cavity” lokuhlola amabhopho ngokuzenzekelayo (Bheka iFigure 10). Umphathisi wesezi lemali wesegapha lufakwa ngezinye zezindlela ezinconywa ezincono iziphumo, kodwa leindlela incedise ukubuyela phambi komsebenzi wesibhileyo ngokuba ungene umkhuthazo omobayili phambi komnyango wesibhileyo. Lwendawo, uphawu olungulunga akukho okungavunyelwe futhi ukuhlola kwayo kanye nokusetyenziswa kufanele, ngasemva kokuba kunye nobucayi besibhileyo baxoxwa ngokubanzi ngesinye sesiphumo. Isifundazwe esisisho sisindumelela ukuthi sikwenze imikrosi yasebenzi ngokulandelayo.

Yekumusha lokugcina ngokulandelana kwi-sewing yesiboniselo, Softwear Automation Inc. esihlaleni se-Atlanta, ayikho e-ITMA 2023. Ukuphawula kweSewbot® wakhiwa umsebenzi wokuqinisekisa okubonakaliyo kwezilimi zokusebenza ngonyaka we-2012, nesithombe sokuhlala ukuthi amagunyazwe angasebenzisi abangcono. Isistimu sakhe sisetshenziswa isimo sokuqinisekisa sasemfanelo wesivisijoni lesi-sekhukhune nokubuyekeza amarobatika angaphantsi ukuvavanya amabhopho bese usetyenziswa ngokubizwa ngokufanele kusenziwa kwezinye zezigunyazwe ezikhona. Esikhundleni sokusebenza kwe-T-shirt, i-Sewbot yakhiwe njenge-umthengiso wesicelo phakathi wezi-$5,000 kwi-mesi yezulu ngokwesikhatsi. Ngokungababiwe ngaphambi komhlaba kwesikhashana sesi-Textile World, umsebenzi omncane wesifundo sokuqinisekisa wasethatha u-T-shirt olwenzeleyo emizuzwana angakhulu.

Amatekonoloji Abasebenzayo Alternative

Kwesihlanu, amanqaku okanye olunye kwezindlela zokusewa zazibonakale kakhulu ngaphambi kokuthiwa e-ITMA. Bazo kuhluzelelwa amagama esebenzayo lokusema noma i-ultrasonic welding, u-adhesive bonding noma i-printed embroidery. Amagama okulandelayo aziqinisekileyo ukuba ezincedisiwe ngaphandle komphendisi wesenzi, ngisho ngokubanzi kunye nokusewa olunye. Ukusema i-ultrasonic noma u-adhesive bonding ayiqomekezekileyo yamathetho, kodwa izicatshulwa ezifanelekileyo zibe ekuthathweni le-ITMA.

Optron Textile Machinery ebekweni lesi-Spain eyayiphelela amarholi lwe-calendar oza kuhlola imigca elisetyenziswa lokugcina amasimu ase-quilting phakathi kwebhankiso noma umthamo (Bona ngonyaka 11). Abasebenzisi ababili base sewing machines, Juki Corp. kunye ne-Brother Industries Ltd., abesihlanu kule-Japan, baziphelela amanqaku amaningi elisebenza lokugcina amasimu amadala amade akusenziweyo. Ngokuthiwa Hayes kunye no-McLoughlin7, amasimu amagciniweyo angapheleleyo, kodwa baza kuhlola amajoint amancane kunye namahhula emasimu engasebenziweyo.

Umkhakhi wokuqala wesibophelele (kunxantatho kwezintsha): Amatekonoloji amandla okanye aphandle kweziseko zisebenza zizama ukuba ezilayiswayo nge-Optron; kunye nokuhlanganiswa kwamaxesha ngokubondwa nge-Brother kunye nomaxesha ofumanekayo

Ukuhlaba kwezinto ezinethiweyo kukholelwa, kodwa iindlela esidingiwe yahlukile kakhulu nge-ukusindiswa ngokuhlambulula umthengiso wemali ethiwe phakathi kwezilayisi zomsebenzi. Imithengiso yemali yaziqhutywa njenge-tape, okuthiwa ngaphandle kokuthiwa ngumthengiso wemali wamalayiselo, okuthiwa ngaphandle kokuthiwa ngumthengiso wemali wamalayiselo, okuthiwa ngaphandle kokuthiwa ngumthengiso wemali wamalayiselo. Ukubondwa kufanele kuzohamba ngaso sikhundla sabantu ababili abangene nge-ITMA ngenxa yokuba lemfazwe yakwabo yebonding machine iyithumele yiyeke yezilungu zemali eliqhutyweyo (Bheka eFigure 11). Izilungu ezibondwe zihlaba izigcino zasekhaya zikuphi ndawonye kanye nokuthiwa ngaphansi kakhulu kunye nokuthiwa angavuliwe kakhulu ngazo zonke iziseko ezisenzelayo.

Umkhakhi wesibophelele 12: Umsindo wesichotho esenzelayo ngokubondwa nge-Kornit Digital

Ithemba esingakweni kwisezokubhulula kusetyenziswa ngalokhu kwakubonwa ngeKornit Digital. Ukusebenza kweqinisekiso lokugcinwa lwakuxoxwa njengesinye sokuqala sokuphumula kudibanisana kodwa le T-shirts. Amaphrinta akho edirekthi yamathebha ayahlukileyo wamuchedwa ukwenzela ukuthola iquka lokusebenza ngendlela yokuhlala emfuneweni okuyona ukuba ukuhlala kanye nokuhlinza izigaba ezikhulu eziphumayo ngokushesha. Ngokusho kwi- Figure 12, kungavakali ukubonisa phakathi komoya okanye kokuthi amaphrinta kunye namasayithi ngokumunye wezi zintathu. Isiphumo esiphephileyo sokusebenzela kweqinisekiso lokugcinwa lwegcino lwezindlela ezidingekayo. Ukunceda ukuthi akhiwe into yezinto ezingaphandle kwalokhu olungaphansi kwebhululo, lokhu kuzokubona ukuthi ikhutshwe iphakathi nemibhalo yakhe ngokushesha futhi ngokulandelayo.

Umgca Wemathathu Lomkhankaso 4.0

Umkhakha wezindwangu wawuphambi kwezinguquko ezintathu zezimboni zangaphambili futhi usuzilungisa ngokuzimisela ekuguqulweni kwesine okwenzeka manje. Njengoba ziqhutshwa futhi ziqhutshwa ukuthuthukiswa kobuchwepheshe bolwazi, izinto ezintsha ezinkulu ze-Industry 4.0 zisekelwe ekuguqulweni kwedijithali. Ihlose ukuhlanganisa umhlaba wangempela nowokuzenzakalelayo ngokusebenzisa izinhlelo ze-cyberphysical futhi ixhumanise abantu nemishini nge-Internet of Things (IoT) 9. Lokhu kuvumela abakhiqizi bezingubo ukuba baqaphe izinkinga zokukhiqiza ngesikhathi sangempela futhi balawule inqubekela phambili yokukhiqiza kude okwenza izimboni zezingubo zihlakaniphe. Izakhi ezibalulekile zobuchwepheshe yi-IoT kanye nenethiwekhi esebenzisanayo. Umgomo oyinhloko uwukwenza ukukhiqiza kube ngcono futhi kukhiqize kakhulu. Njengoba kubonisiwe e-ITMA 2023, i-Industry 4.0 iyinkulumo esebenzayo ezinkampanini eziningi zokwenza indwangu ezinokuqamba okuningi kwezobuchwepheshe okuzayo. Njengoba kucatshangelwa i-Industry 4.0, imishini eminingi yokusika nokuthunga.

amaphrodyisi amahlalekile ngokubanjini kunye nezilungiselelo zesayithi, zisebenzela ukuvumelanisa izindawo zakho ezifanayo. Zihlaba ezimbini zazokuthola kwi-ITMA. I-Zünd Systemtechnik wakhe ithetho nesi-Mind Technology esitshalweni sezintathu i-Portugal ukuze alinde umsebenzi wasebenzisi wayo. I-Juki usetyenziswa ngokuba uhlanganiswe inqanawe yesayithi, elishwa ngo-JaNets1. I-Mammut wakhe ithetho yezinto lesoftware elingezwa lokufunda imigomo yokusebenza kwesayithi, ukucabanga amareyithi angama-produktivithi kunye nokuhlola ukusetyenziswa komphendulo. I-ACG Kinna Automatic usebenzela ukusetshenziswa kwisebe lapho akhetha ukulandzelwa kakhulu kwezindlela ezidingekayo, kodwa futhi ukuphatha nokudibana ngezinhlanhleni zomoya ngokukhona.

Ngokuhlola ukuthi lokucacisa umthakathi, izindlela ezincane zikhululekile kuzothelelwa ngokubanzi, njengomashayela ophenduliwe nokumthetho womdabu ohloniphe. Ngemva kokugcineni, amasistimu wokuqinisekisa umthakathi awakhulisanga futhi wazama ukuba amaphathisithi walalele kunye nokukhombisa ukuvavanya iimpendulo zophrojekthi. Ukuphatha kumaphandle komsebenzi wesintu, imiphumela yamandla ayaziwini ngaphandle kokufuneka kuhlala akhulume phambi kokuba iimpendulo zihlobene nendawo yokusetyenziswa. Ngokusebenza kwezindlela ezincane ezinhloko zokubheka, umthetho womdabu wamanje uzame ukuphendula amaphathisi wezinye izinto nokuthuthukisa uphawu olungena kwiindawo zokusebenza ngokushintsha izidingo ezibhedlwane. Ku ITMA, Serkon Tekstil Makina yalandelisa isistimu esingeyenza ukubheka kwezifotho eziqinisekiswe ngokusebenzisa ukubheka okuthile nokumthetho womdabu. Isistimi sakhe sikhishwe ukuba sihlalese inani lezi zinto ezinikezeli kanye nezi zinto ezinikezelwe ngokwesobunyawo.

Izindaba ezikhoyo ezenziwe ngamakhonjisi wezintshisekelo zokubili yilimi elishona lapho amakhonjisi wamanje wakwazi ukwenza ukuqala kwezinto ezifanayo. Ngokugcina umkhonjisi we-Artificial Intelligence (AI) ngemibuzo yokuxhumana nge-CAD, i-intelligent CAD system yiyo yenza izidingi zokudigita phakathi komunye kwezinye izindlela ezithathelako kanye nokufinyelela izinsiza ezijikeleleyo ezintsha. Lolu hlobo lokuhlola kumangeni abaningi abaningi amandla okuthile kuhlelwa lokuhlola ukuba akhethwe amandla apha apho akwazi ukusuka kwezinto ezinomsindo. Umthetho wesikhwama, Myth.AI, wahamba ukukusho umvume we-AI wokuhlela amapattern esetyenziswa kwi-ITMA eyenza izinkinga ezimbili ezinokuqaleni ezinokuthiwa ngokuphelele.

Ngokushesha, isibuko esithandwa sokuqala — Industry 5.0 — usudisiwe ngaphandle kakhulu ngeindlela yobhotile, ngalokhu amaninimandi akhawukile kuqala kwi-Industry 4.0. Ngakwesikhatsi sokuqala sokuhlola i-EU9, i-Industry 5.0 ihlala idinga izinhlamvu zonke ezikhona phambi kokuthi ukusebenzisa nokuhlinza kwemfanele yokugcina. Ukubuyela ifokosi eliphambili lokusebenza kanye nokulula okunye ukuze kube lapho ubuyekezwe ukuba imali kunye nezinto ezizidingwayo, uzama ukufaka ukusuka kwisebe nokuziphindaphinda kanye nokuhlola obungane ngokwesifundazwe kwi-Industry 4.0. Lolu hlobo lungekho enguquka, kodwa. Izinhlangano zokuhlola, izindlela zokuphatha nokuhlola (ESG) noma izigaba ezintathu zokuhlola zibeziphathelwe ngazo zonke izinyanga ezilandelini eziqondisiwe ngazo zonke iziko-lobhotile lehlulekile. I-Industry 5.0 ibheka ukuthi abantu, umsizi wenkolo, kunye nezinto ezinethando zihlukaniswa njengomthetho wesikolelo somphakathi wasebhotile webobhotile nobhotile nobothili. Ukususa i-Industry 5.0, izibonelo ezisetswe zokumakhiwa kanye nokungavakalayo kukhishwe ukuba bakwazi ukucopha ITMAs eneenkingeni.

Umculo Wokubuya

Amahlelo amahlukayo ezibizwe kwi-ITMA 2023 zazibhaliswayo ukuvumela izinto eziphumaphansi zokuphatha ngokulungileyo kwi-processi ye-cut-and-sew yemithombo. Amahlelo akhona abangasebenzi kakhulu ngakwesobunxebo nokusetyenziswa. Kuningi lomsebenzi oluhlukekileyo lwamathombi yokuphatha ngokuzenzakalo nokuseva kubonakali le-ITMA 20191. Izindlela ezikhona ezihlanganiswayo kucutsheneyo kukuba kuhlanganisiwa ngendlela yezwi-mashinayi emuva nokugcina kucutsheneyo, upopularit shi yezwi-mashinayi yokubala imijenti, kunye nokuphatha kakhulu kwemashinayi ekugcinwa ngezinto ezindala ezinkulu. Ngenxa yokucutsheneyo, i-sewing automation ikhona esebenzelayo ngokuthabatha izintlonzo ezincane ezifanele, okungavalelako amanye amagama okusevayo kwi-configurations ezahlukayo. Inkinga yeso seshona esethembekayo isenza inkinga lokhu ukuba umsebenzi wemithombo nemithombo yemithombo yemithombo yamatextail ne-apparel izinga lohlola kakhulu ngalinye ilanga ngokubheka ngokuthi siyaziqondiswa ngokupheleleyo kulesi sishonaleni lesine njengoku-4.0.

Iingxelo

1. Suh, M. (2019). Ukugcina nokusema amandla ngokuzenzakalelayo kwi-Industry 4.0 e-ITMA 2019. Journal of Textile and Apparel, Technology and Management. Isibonelo Esikhethwe, 1-13.

2. Aeppel, T. (2022). I-Robots zisetyenziswa ukwenzela umsebenzi omusha: ukuhula izinsimu ze-blue jeans, Reuters, Yikuyiphiwa ngesi-Juli 2023 kwise https://www.reuters.com/technology/robots-set-their-sights-new-job-sewing-blue-jeans-2022-12-12/.

3. Davies, G. (2021). Ngaphi kunye ne-on-demand manufactur-ing ifanele yezifundo ezithile? Techpacker, Yikuyiphiwa ngesi-Juli 2023 kwise https://techpacker.com/blog/design/fashion-on-demand-manufacturing/.

4. Li, R., Zhao, S., kunye ne-Yang, B. (2023). Ukubona kumthetho wokusetshenziswa wesiqephu esikhundleni sokuqala sokusema amandla ngokuzenzakalelayo kwi-process yokusema imibhalo yesithathu. Applied Sciences, 13(4), 1-14.

5. Francis, S. (2019), SoftWear Automation ukhuluma uSewbots njenge-sevisi, Robotics and Automation News, Ifumaniswe ngokuJula 2023 kwiseveni https://roboticsand automationnews.com/2019/02/05/softwear-automa-tion-launches-sewbots-as-a-service/20847/#:~: text=For%20a%20monthly%20fee%20starting,and%20three%20shifts%20a%20day.

6. Textile World (2019). Sewbots® Ukubuyisana Okungakho Lwesiko Lokusema, Textile World, Ifumaniswe ngokuJula 2023 kwiseveni https://www.textileworld.com/textile-world/2019/07/sewbots-transforming-the-sewn-prod ucts-industry/.

7. Hayes, S. kunye noMcLoughlin, J. (2015). Ukusema kwemali, Kwi-J. Jones kunye noG.K. Stylios (AmaEds.) Joining Textiles (amashezi 66-122). Sawston, Umsinga WaseNgesi: Woodhead Publishing.

8. Sarkar, J., Rifat, N. M., Sakib-Uz-Zaman, M., Al Faruque, M. A., kunye noProttoy, Z. H. (2023). I-Teknoloji Esikhulu Sokusebenza Kwemali. Kwi-M. Rahman, M. Mashud, kunye noM. Rahman (amaEds.) Advanced Technology in Textiles: Fibre to Apparel (amashezi 177-231). Singapore: Springer Nature.

9. Muller, J. (2021). Amaphutha Okukhuthazeka kwi-Industry 5.0, European Commission, Yikuphiwe ngemvume kwesiNgedelesizulu sesikhatsi somwe 2023 nge-https:\/\/op.europa.eu\/en\/publication-detail\/ -\/pub-lication\/8e5de100-2a1c-11eb-9d7e-01aa75 ed71a1\/language-en.

Ingenzi yeHlupekiso: Dr. Minyoung Suh udlamani wesikhashana esincinci esiWilson College of Textiles kuNC State, Raleigh, N.C., kwindawo yamaTextile and Apparel, Technology and Management. Le sithombe sikhethekileyo siveze weSuh ephathwe kwi-Journal of Textile and Apparel, Technology and Management (JTATM) kwiNC State Wilson College of Textiles.

Ekhulu/Lesibini 2024