hat embroidery machine factory

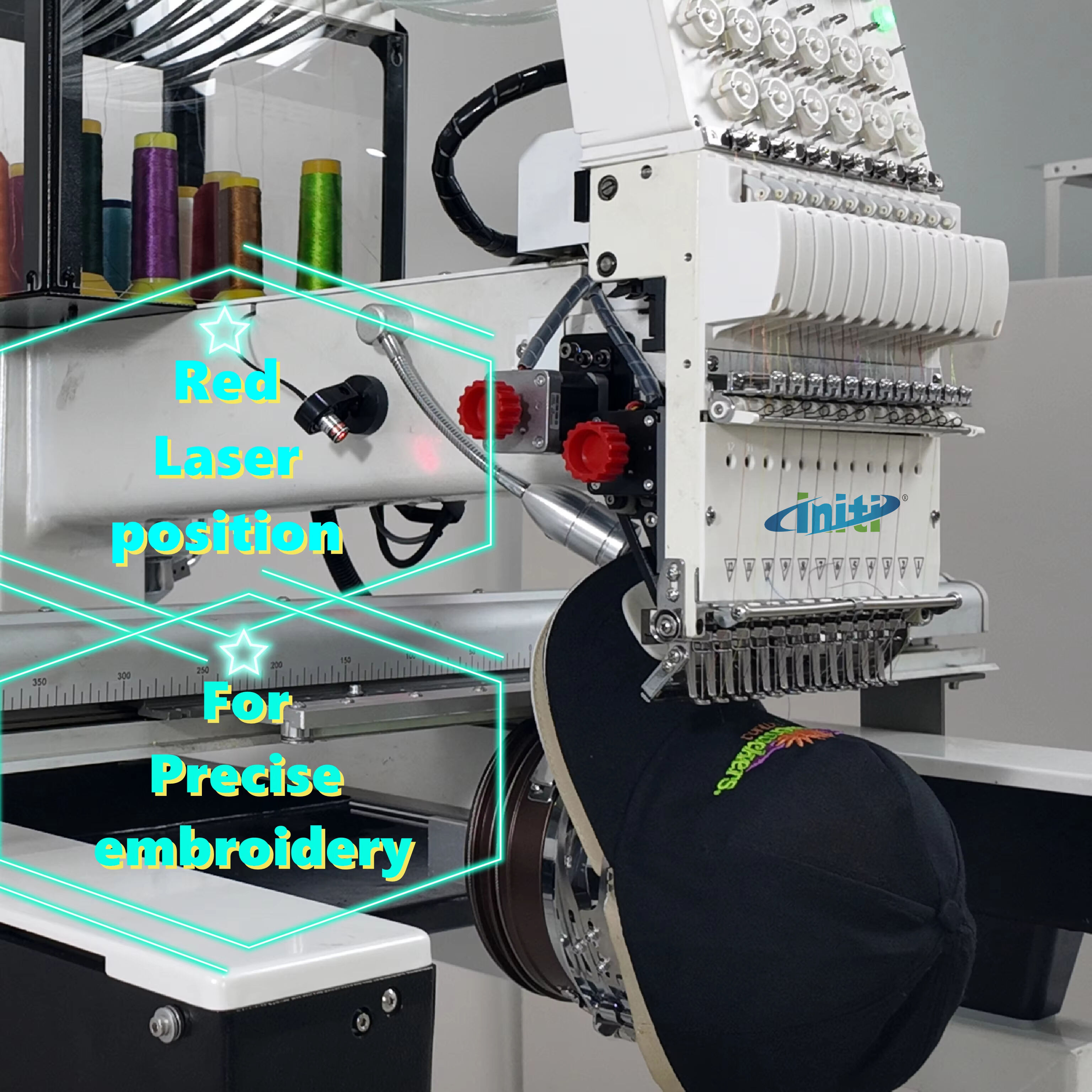

A hat embroidery machine factory represents a cutting-edge manufacturing facility dedicated to producing specialized equipment for hat and cap decoration. These advanced facilities combine precision engineering with automated technology to create machines capable of delivering consistent, high-quality embroidery on various hat styles. The factory incorporates state-of-the-art production lines equipped with quality control systems, ensuring each machine meets strict manufacturing standards. Modern hat embroidery machine factories feature computer-aided design and manufacturing processes, enabling the production of machines with multiple needle configurations, automatic thread cutting systems, and sophisticated control panels. These facilities typically include research and development departments focused on innovating new features and improving existing technology. The production process encompasses assembly lines for mechanical components, electronic systems integration, and comprehensive testing phases. Factories maintain specialized areas for frame construction, motor assembly, and control system installation. Quality assurance protocols include rigorous testing of embroidery speed, precision, and durability under various operating conditions. The facility's output serves diverse market segments, from small embroidery businesses to large-scale industrial operations, offering machines with varying capabilities and specifications to meet different production needs.