safe cap embroidery machine

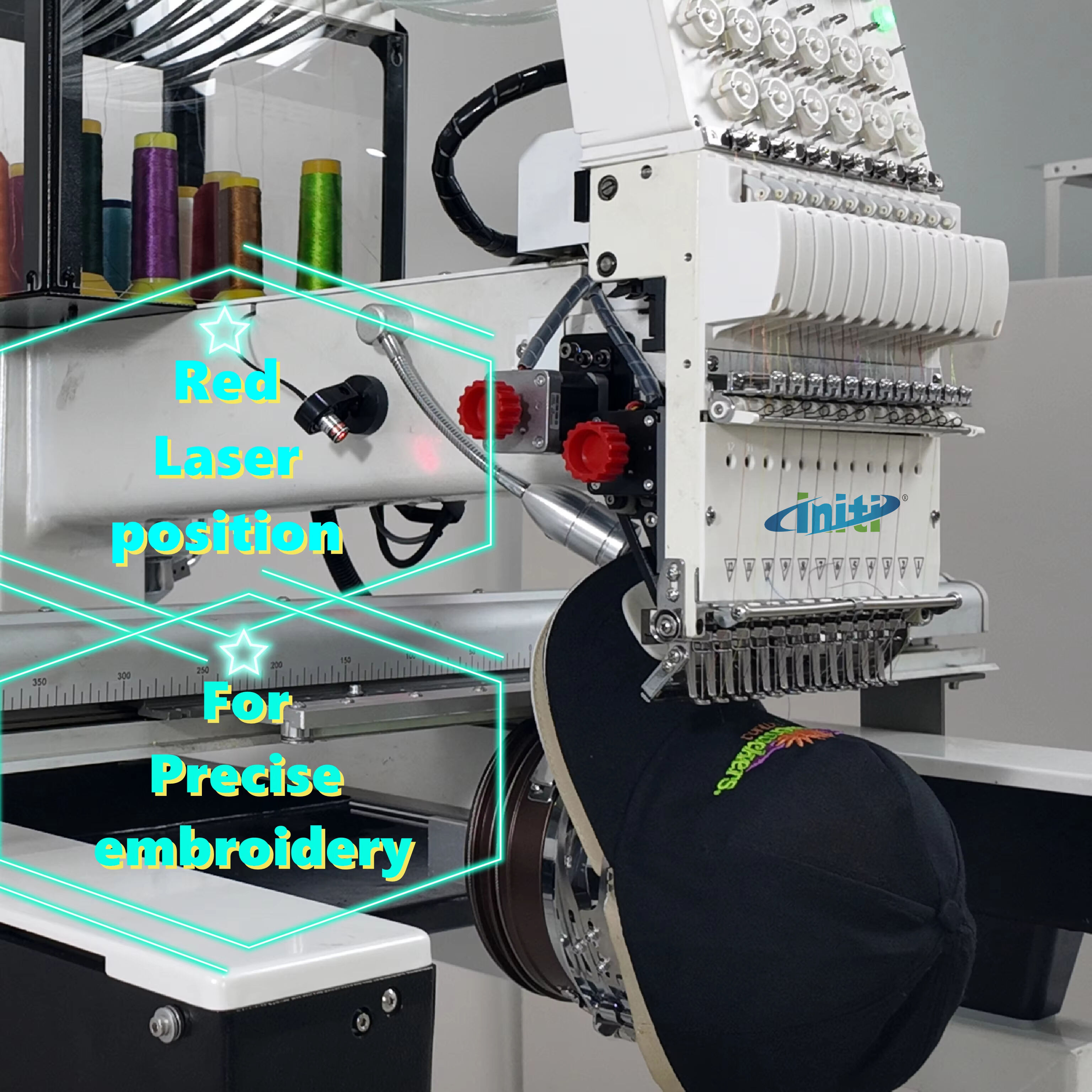

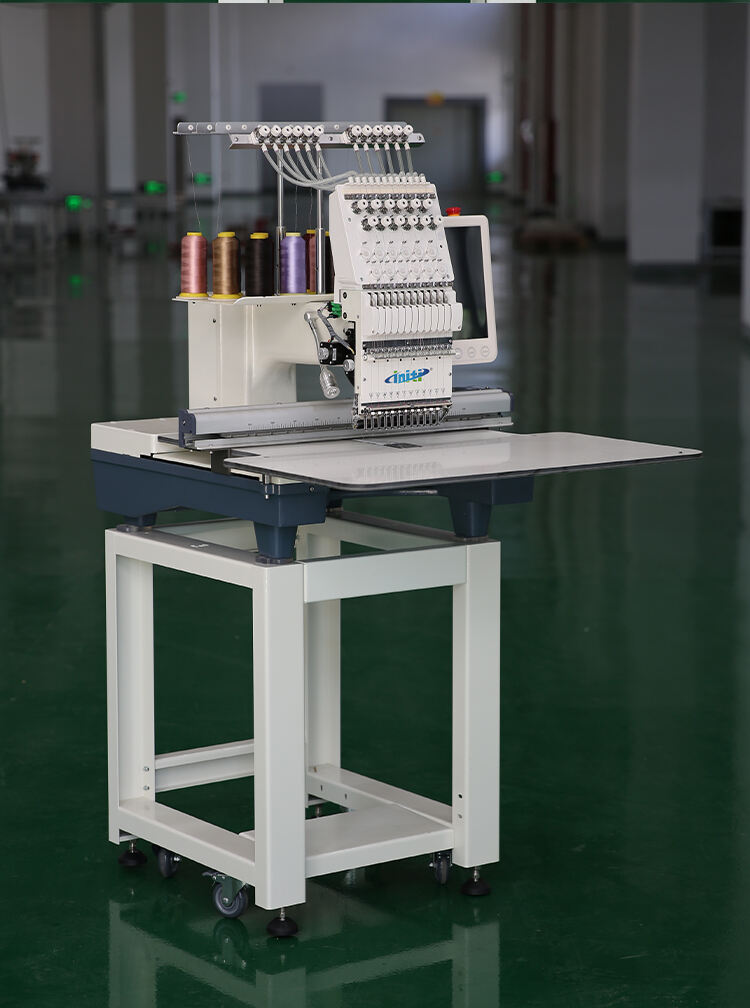

The safe cap embroidery machine represents a significant advancement in headwear decoration technology, combining precision engineering with user safety features. This specialized equipment is designed specifically for embroidering caps, hats, and other headwear with exceptional accuracy and consistency. The machine features a dedicated cap frame system that securely holds the cap in place during the embroidery process, ensuring distortion-free designs. With multiple needle positions and automatic color changing capabilities, it can handle complex designs while maintaining high production efficiency. The system incorporates advanced safety mechanisms, including emergency stop buttons, needle break detection, and thread break sensors, making it exceptionally safe for operators. The machine's interface is user-friendly, featuring a large touchscreen display that allows for easy pattern selection, design modification, and operational control. Its compact design maximizes workspace efficiency while providing ample room for cap manipulation. The safe cap embroidery machine utilizes advanced servo motors for precise positioning and smooth operation, resulting in consistently high-quality embroidery. It accommodates various cap styles and sizes, from structured baseball caps to low-profile visors, with quick-change cap frames for enhanced productivity. The machine's memory capacity allows for storage of numerous designs, while USB connectivity enables easy pattern transfers and updates.