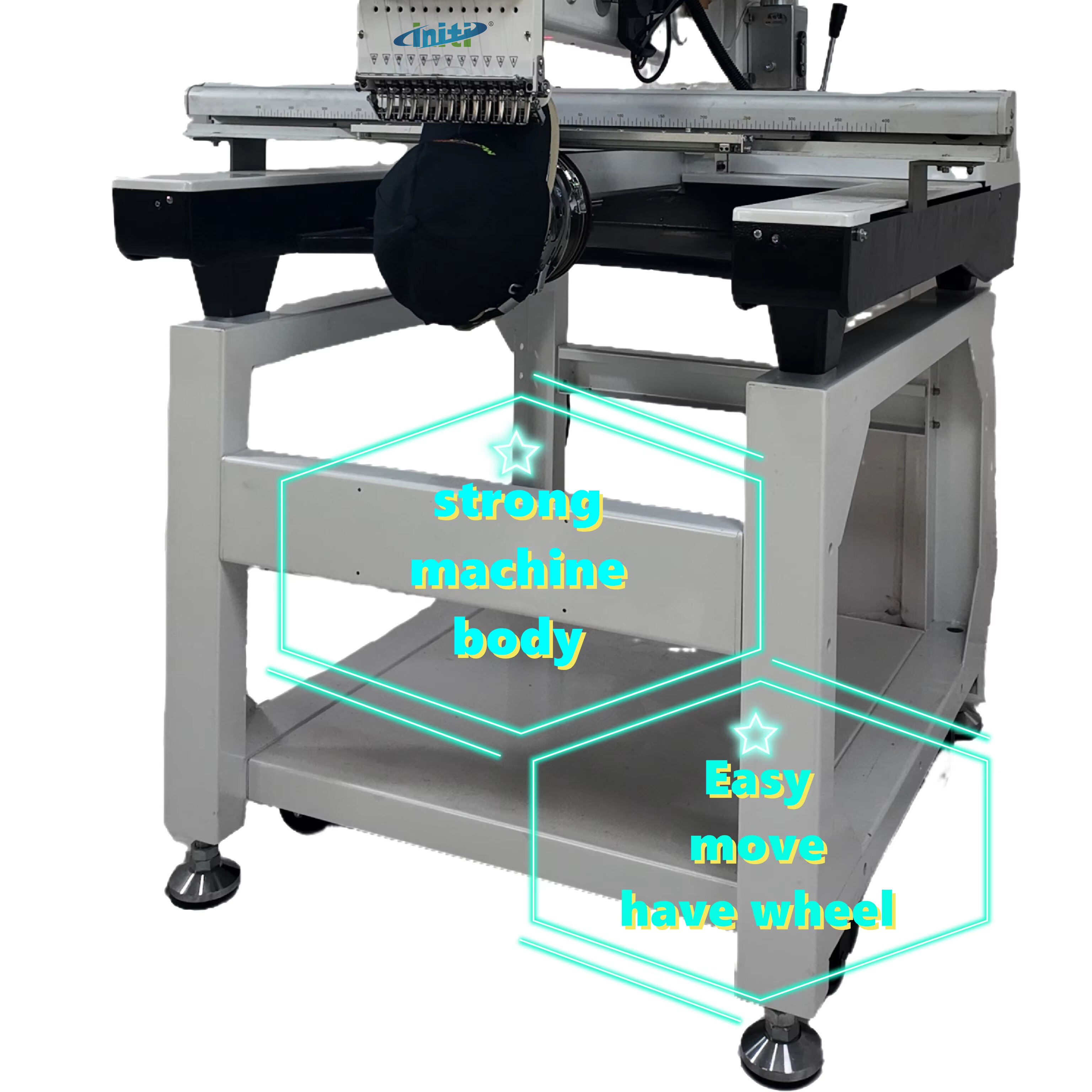

customized hat embroidery machine

The customized hat embroidery machine represents a breakthrough in personalized headwear manufacturing technology. This sophisticated equipment combines precision engineering with user-friendly operation to deliver professional-grade embroidery on various hat styles. The machine features a specialized rotating head design that accommodates different hat sizes and styles, from baseball caps to beanies. Its advanced digital control system allows for intricate pattern creation and modification, with the ability to store thousands of designs in its memory. The machine operates with multiple needles, enabling quick color changes and complex pattern execution without manual intervention. It incorporates automatic thread tension adjustment and real-time monitoring systems to ensure consistent stitch quality. The high-speed operation capability, typically reaching 1,000 stitches per minute, maintains exceptional accuracy while maximizing productivity. The machine's built-in display interface provides clear visualization of designs and operational parameters, while its automated positioning system ensures precise placement of embroidery patterns. These features make it an ideal solution for both small boutique operations and larger commercial enterprises seeking to offer customized headwear.