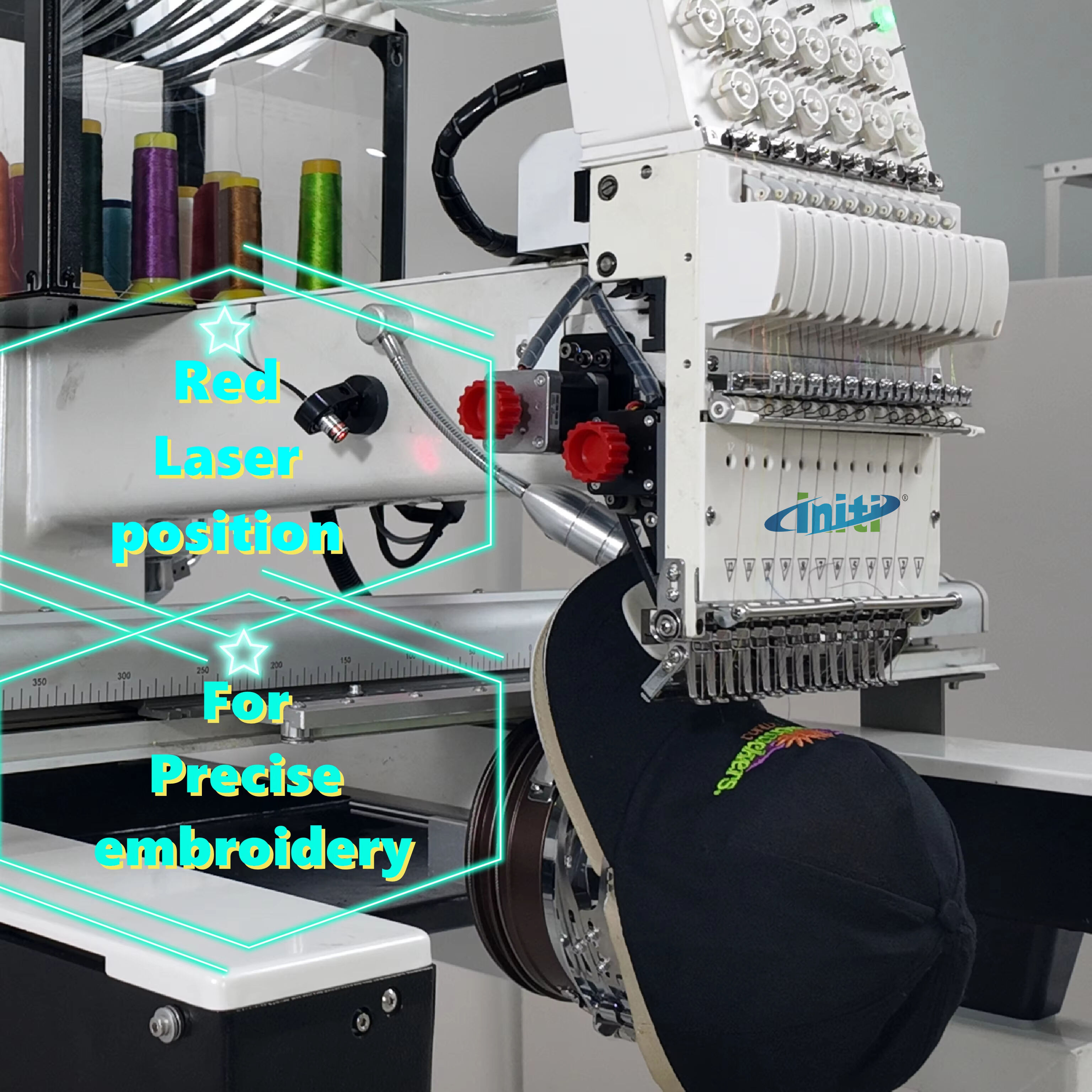

high quality cap embroidery machine

A high quality cap embroidery machine represents the pinnacle of precision engineering in the embroidery industry, offering unmatched capabilities for customizing headwear with intricate designs. These specialized machines feature advanced servo motor systems that ensure precise needle positioning and smooth operation across various cap materials. The machine's innovative cap frame design accommodates different hat styles, from baseball caps to visors, while maintaining consistent tension for optimal stitch quality. Most models come equipped with multi-needle configurations, typically ranging from 6 to 15 needles, enabling quick color changes and efficient production. The built-in LCD touch screen interface provides intuitive control over design parameters, including stitch density, speed adjustments, and pattern positioning. With a maximum speed of up to 1,200 stitches per minute, these machines deliver both efficiency and precision. Advanced features include automatic thread trimming, thread break detection systems, and memory capacity for storing thousands of designs. The machine's robust construction ensures stability during high-speed operation, while the specialized cap driver system maintains proper fabric positioning throughout the embroidery process.